- © 2018 Steve Allen Contact Me 0

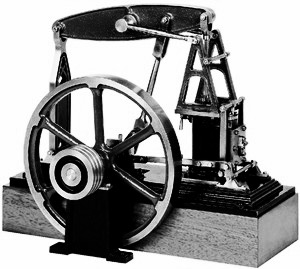

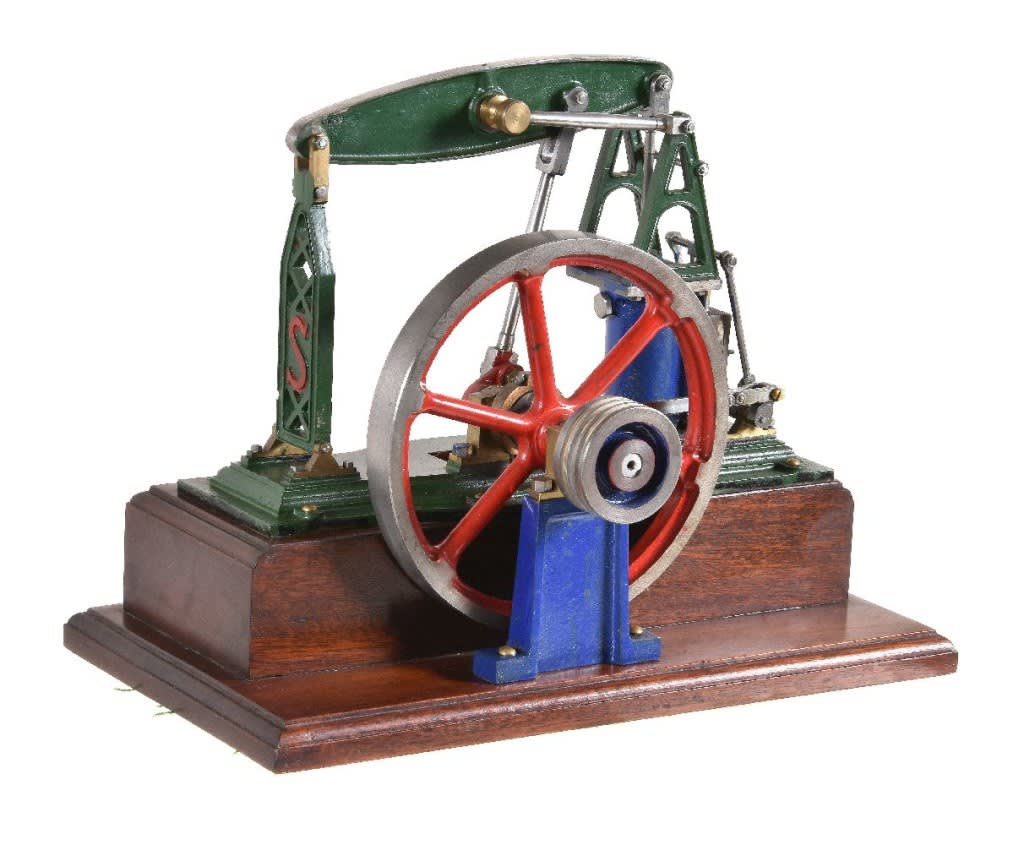

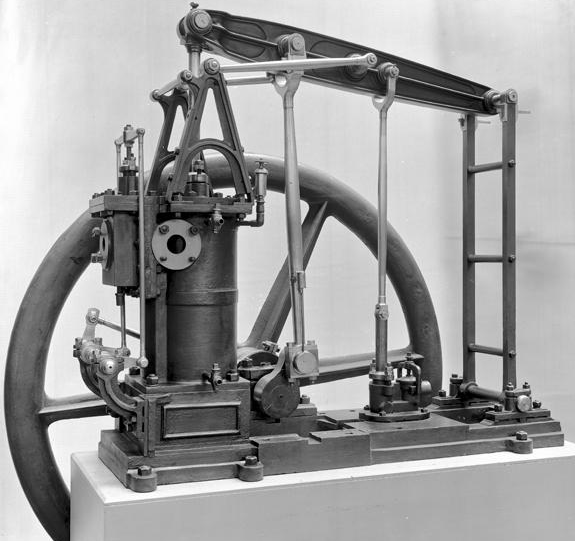

Half Beam

1 in. Bore and 2 in. Stroke

Original Grasshopper Engine

price:

£212

Full set of Castings, Materials, Screws and Drawings.

The Half beam engine design is simpler and less expensive to produce due to it not requiring the complex Watts walking mechanism. This simpler design does however limit the maximum size of the engine due to the beam's mounting. The cylinder is mounted vertically at one end of a cast soleplate. At the other end are bearings for a vertical, ladder, like support, which secures one end of the beam. Above the cylinder are two A frames which mount at the apex, two support rods that mount the middle of the beam. The piston rod then connects directly to the end of the beam. The conrod is mounted between the piston rod and the middle mounting rods. Here is where it gets interesting, the two mounting points for the beam allow it to pivot but also move longitudinally by the ladder support occilating backwards and forwards. The beam pivots on the two connecting rods, the ends of which describe an arc as the piston goes up and down. This arc is the opposite of an arc that would be described by the piston rod end og the beam if the far end were fixed in place, so by allowing this end to move the piston rod end of the beam travels in a vertical plane directly above the piston. No crosshead is required to limit lateral movement of the piston rod. The operation is a bit unsettling at first, as the beam pivots, like a normal beam, it also moves back and forwards longitudinally. Totally unlike a normal beam. The ladder support occilating a small amount. It is the movement of the beam both pivoting and occilating that limits the size of the engines and also the running speed. Cranking up your model to overdrive is not very realistic and may cause eccesive wear. The valving is the same for the beam engine but uses a smaller eccentric rod. Machining is far simpler than the beam as the critical components are the two beam mounting rods which must be identical and the end holes the same separation as the holes for the mounting rods and piston rod.

The half beam appears to have only one advantage over the full beam angine in that it takes up less space but it does have one other advantage that is only discernable when you look at the mounting points on the beam. On a beam both the connecting rod and piston rod are mounted equal distances from the pivot point. On the Half beam the conneting rod is mounted closer to the pivot than the piston rod. This means that the connecting rod travels a smaller distance than the piston rod. The Beam is acting as a lever, multiplying the force of the piston and transfering it to the connecting rod. By mounting the connecting rod closer to the pivot you can increase the force created. Also note the distance between the water pump mount and the pivot, its quite small meaning a short throw pump but with a lot of force. I havn't gone into any calculation but would expect that this is more resistant to varying loads on the engine than a Beam.

Please Consider Making a Donation