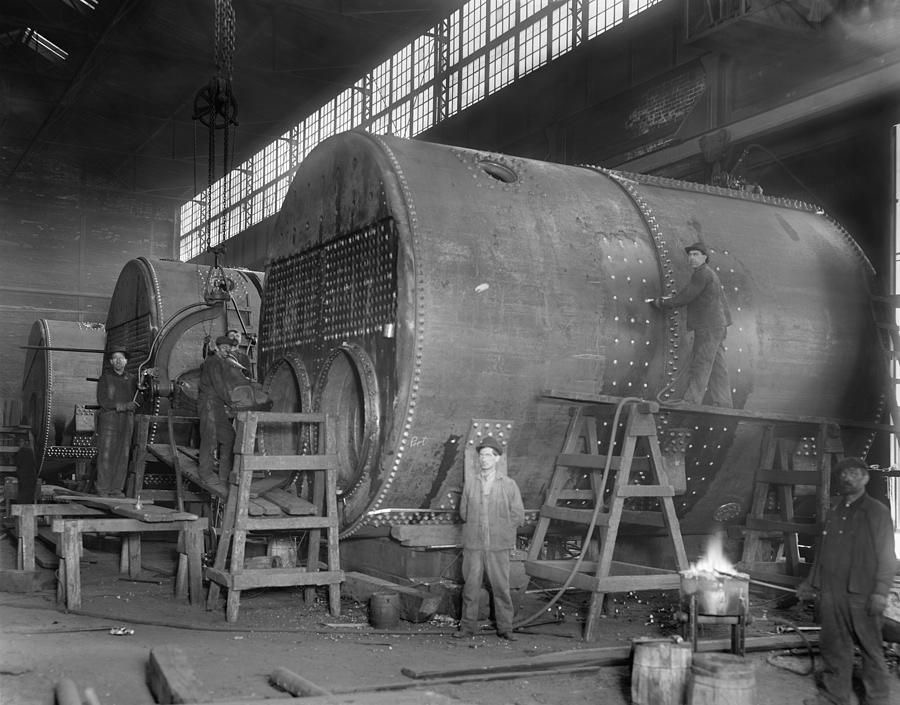

MARINE BOILERS

The 3500 and 4000 Boilers have been specifically designed to replace the 1035 Boiler. These boilers have many advantages, the most prominent of which is that both boilers are significantly shorter than the old 1035 model.

Type 3500 Centre Flue Boiler

Copper Drum (silver soldered and hydraulically tested)

Features

Features Gunmetal Steam Dome

Safety Valve

Water Gauge

Steam Valve

Mahogany Wood Lagging, Brass Straps

Copper Drum painted matt black

5/32 in. dia. Superheater Tube.

The Type 3500 Boiler was specially designed to suit the 10V and 10H engines, and is ideal

for marine radio control models.

A continuous water feed system can be implemented when using the 10V engine with its directly driven feed pump. The delivery of this pump is fed to a check valve (optional extra) for which a seating and blanking plug is provided on the boiler as standard equipment. The 3 1/2 in. boiler ideally complements the No. 10 engines and makes the perfect combination for a marine application.

Please note:—The check valve, pressure gauge and syphon are optional extras.

Part No. Availability

34-50-72350—3500 Finished Boiler with Test Certificate.

Postage Code: A Packed Weight: 3.5Kg.

BURNER

To complement the 3500 Boiler we have developed a new burner unit which is neatly located in the centre flue of the boiler, and is fueled by disposable Butane gas cartridges (not supplied by Stuart Turner Ltd). g g

The burner kit comes with all fittings up to the bottle, which is readily available

Part No. Availability

34-50-72488—3500 Gas Burner Kit (cylinder not supplied) for use with Primus Canisters.

Suitable Gas Canisters:

Butane/Propane Mix No. 2204.

Butane No. 2201.

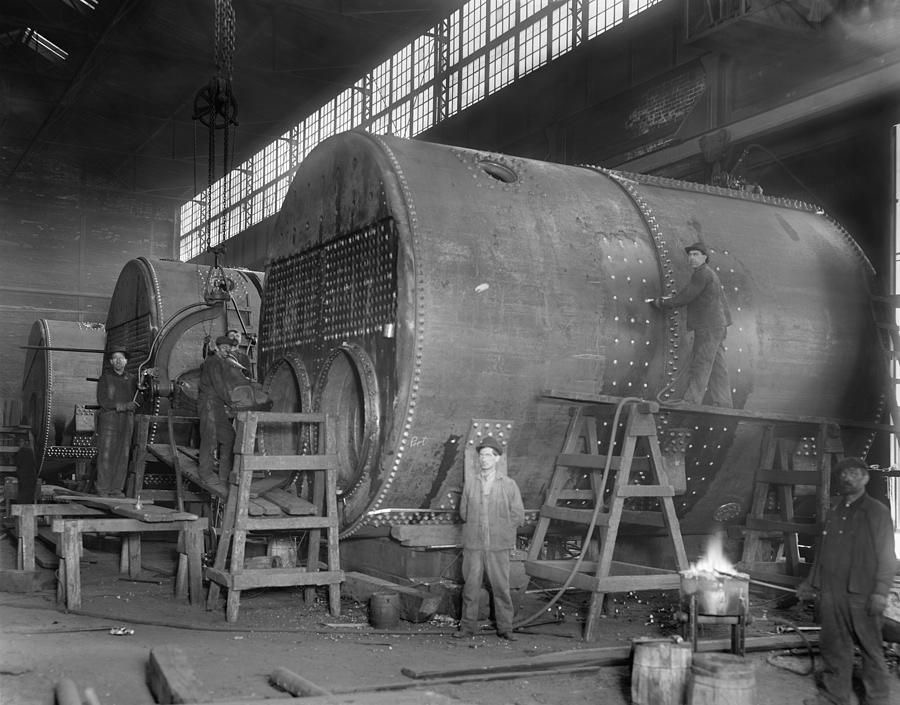

Type 4000 Centre Flue Boiler

SPECIFICATION:

4 in. dia. X Y9 in. (101mm. dia. x 229mm.)

Centre Flue dia. 1 1/4 in. (38.1mm.)

Dry Weight: 2.8 Kg.

Working Pressure: 60 p.s.i. (4 Bar)

1 1/4 in. dia. Chimney

Copper Drum (silver soldered and hydraulically tested)

Features Gunmetal Steam Dome

Safety Valve

Water Gauge

Steam Valve

Mahogany Wood Lagging, Brass Straps

Copper Drum painted matt black

3/16 in. dia. Superheater Tube

The Type 4000 Boiler has been designed with the D10 and Score engines in mind and would be ideal for a remote control installation.

A continuous water feed system can be implemented when using the D10 engine with its directly driven feed pump. The delivery of this pump is fed to a check valve (optional extra) for which a seating and blanking plug is provided on the boiler as standard equipment.

Because of its size and steam output this boiler could well service some of our other engines such as the Beam and Victoria range.

Please note:—The check valve, pressure gauge and syphon are optional extras.

Part No. Availability

34-50-72351—4000 Finished Boiler with Test Certificate.

Postage Code: B | Packed Weight: 4Kg.

BURNER

As with the 3500 Boiler we have developed a burner specifically for use with the 4000

Boiler. This burner also features neat location in the centre flue and is ignited safely while in this position.

Part No. Availability

34-50-72489—4000 Gas Burner Kit (cylinder not supplied) for use with Primus Butane/Propane Mix No. 2204 or Butane No. 2201.

The gas canisters are not available from Stuart Turner Ltd.