- © 2018 Steve Allen Contact Me 0

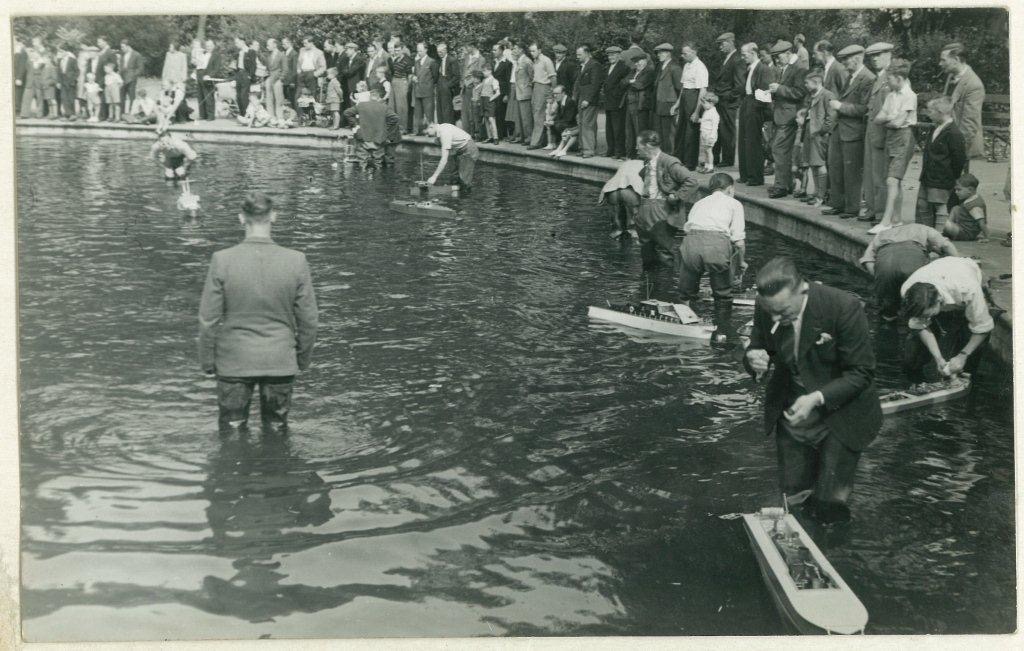

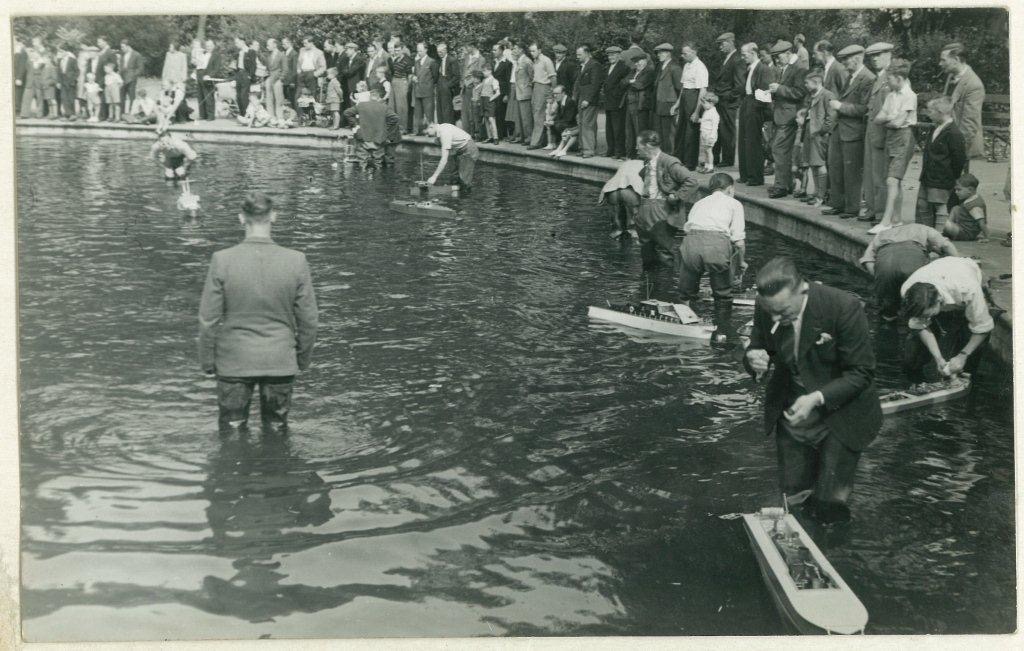

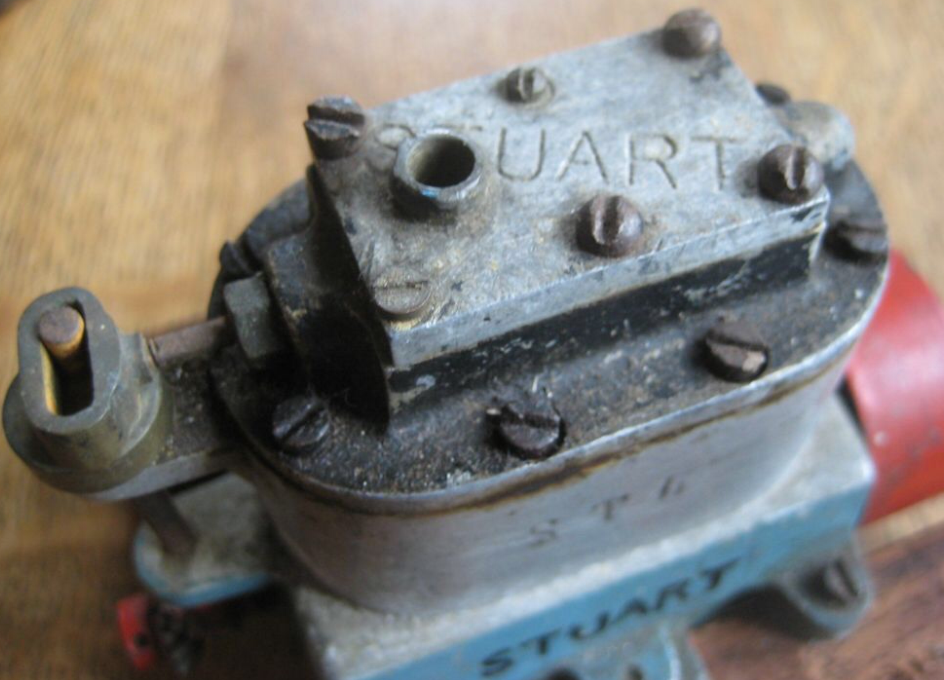

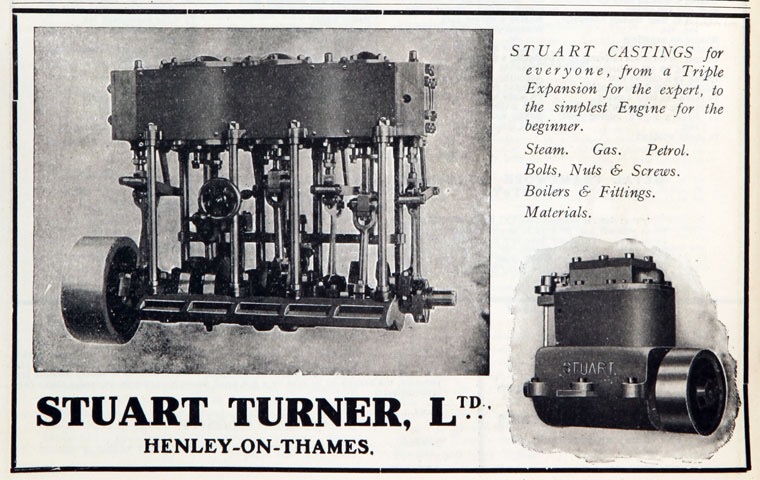

No. 1a M.T.B. "The Featherweight."

Casting and Materials

Cast iron:- fly wheel, aluminium cylinder casting, crank chamber, steam chest cover.

Cast mild steel:- crank shaft

Gunmetal:- valve, slide crank, disc and gear castings.

Sundries:- Brass liners and all steel rods, screws and working drawings, including finished bevel gear wheels.

(weight packed 2 lbs.)

Postage 4d. extra … £0 8 0

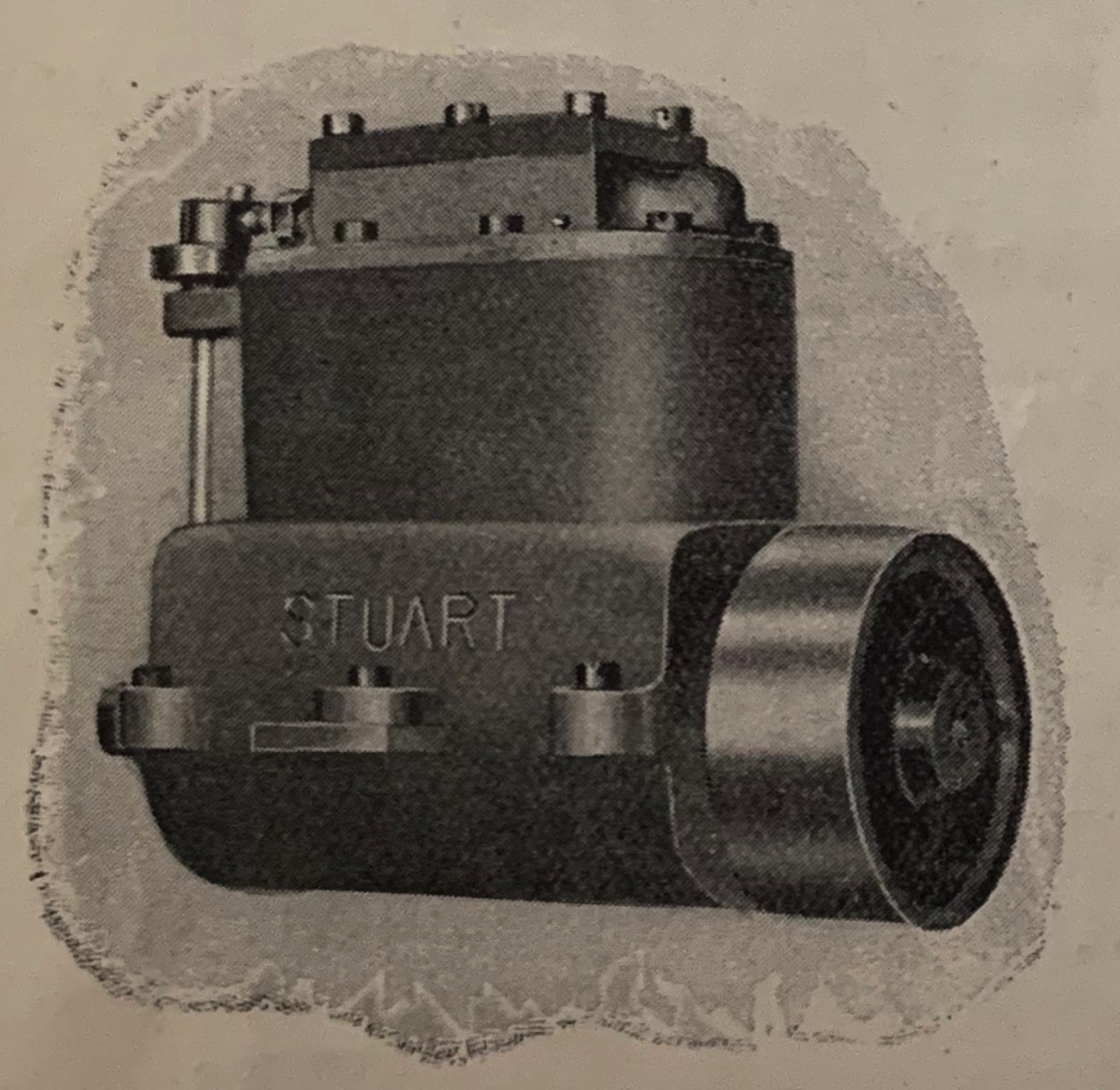

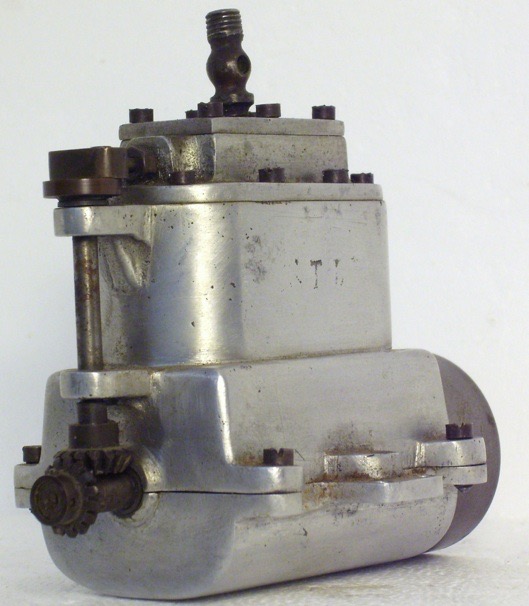

This is a very nice little engine, made from aluminium castings, this material whilst lightweight it is not suitable for some uses. The cylinder bores would very quickly wear out so instead, triple drawn brass tubes are fitted into the casting as cylinder bores. The drawing process work hardens the brass to increase its wear resistance. The crankshaft appears to run in small bearing inserts sandwiched between the cylinder block and sump castings. A small bearing insert also appears to be fitted to the top of the valve gear rod. The gearing on this engine is much improved using a pair of bevel gears, one on the end of the crankshaft and another on the gear rod. This rotates a very small crank disk fitted to the top of the gear rod. A pin fitted into this runs in a "Scotch Crank". You can see this clearly in the third picture, the "Scotch Crank" converts the rotary motion of the gear rod to a linear motion for the valve rod. Interestingly the side has "S T L" stamped into the side of the cylinder casting. could it mean Stuart Turner Lightweight? please let me know if you know. ALso note that there is no cylinder cladding fitted and that the casting is cot contoured to the cylinder bores. One of the issues with the small model boat engines is that they often used Flash boilers rather than Boilers to produce steam. Flash boilers consist of a single very long tube would round inside the boiler casing and heated with a burner. Instead of raising water temperature to above boiling point and releasing the stored steam when needed, a flash boiler is empty until steam is required whereupon water is pumped into the tube which rapidly boils and is rased to superheated levels because of the high temperature and small volume. Because the steam is extremely hot it is not suitable for engines with brass cylinders or pistons. Flash steam used in engines with brass or gunmetal pistons or bores will rapidly suffer wear. Thus this engine is not suitable for use with Flash Steam. When designing Flash steam boilers care is taken to avoid any 90 degree bends in the piping as the superheated steam will 'wear' out the piping at the corner.

Please Consider Making a Donation