- © 2018 Steve Allen Contact Me 0

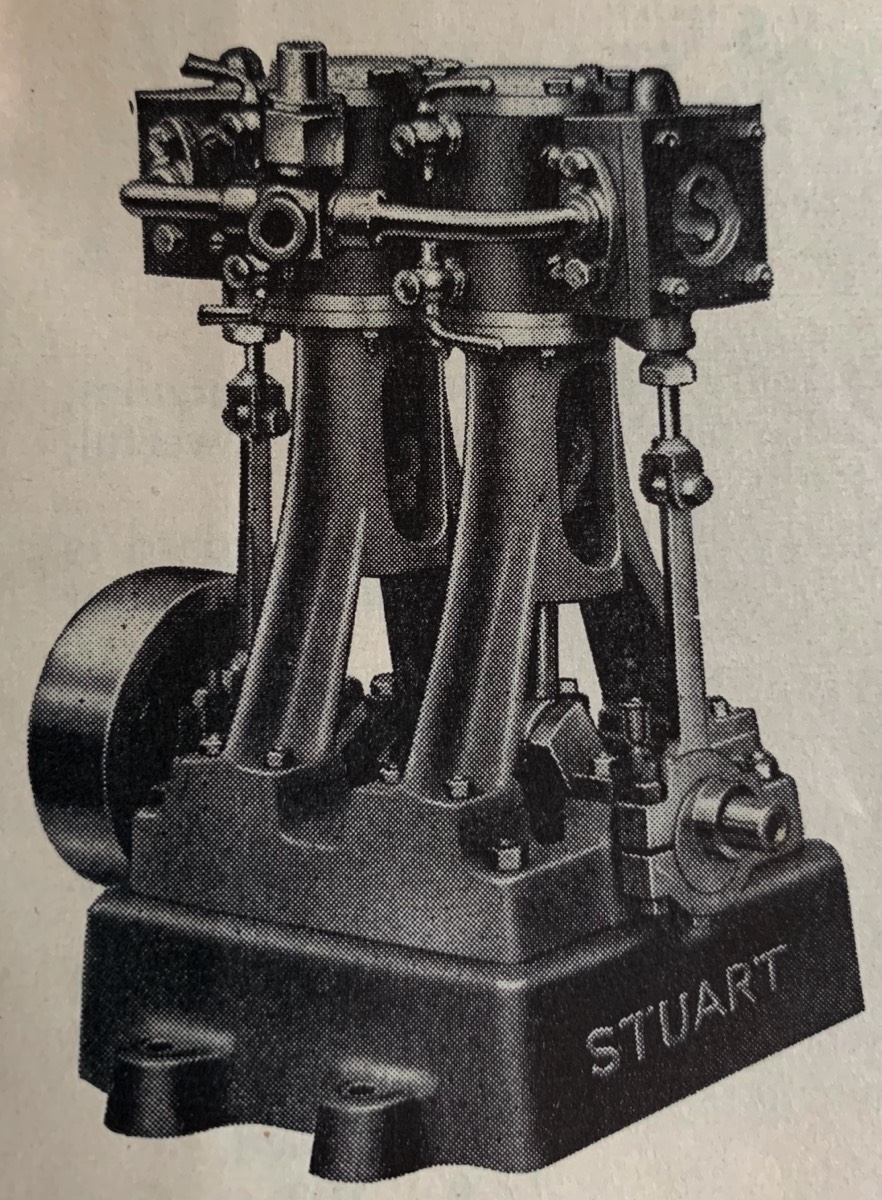

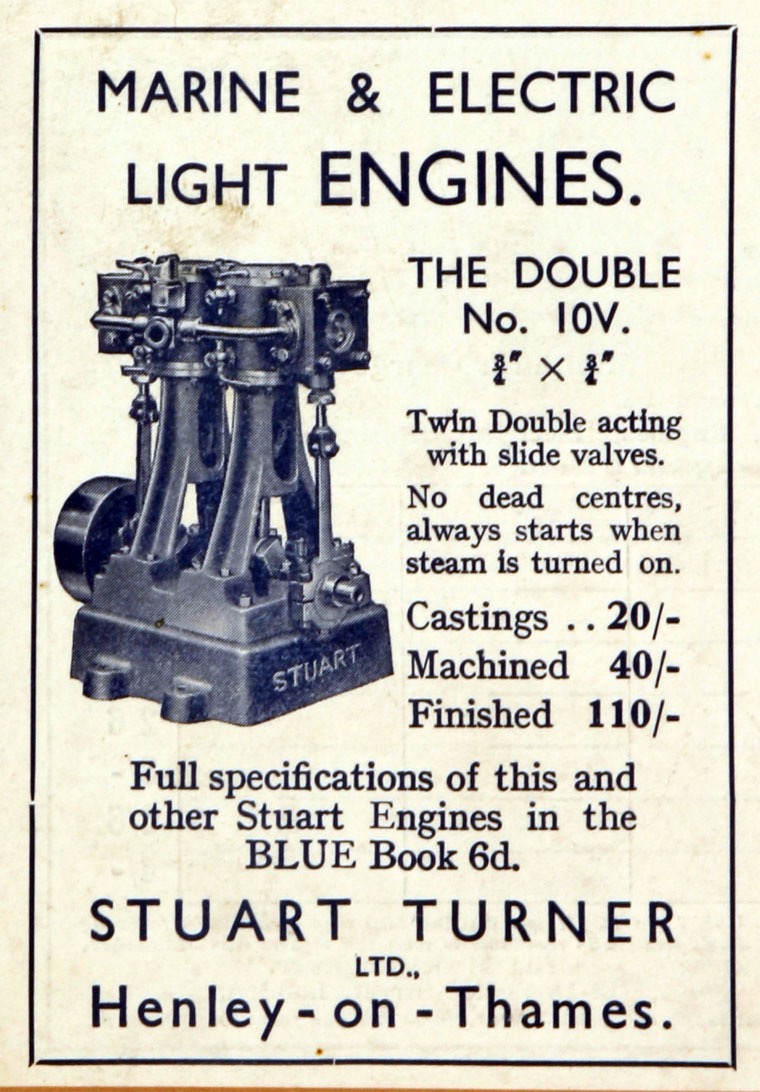

THE DOUBLE 10

VERTICAL

Reversing Gear is not supplied

Height (on Boxbed) … …6 1/2-in

… … (without Boxbed) …5 1/4-in

Width … … … … … … … 3 in

Length … … … … … … 5 1/2 in

Weight (without Boxbed) 3 lb.

The Engine must be seen to appreciate the thoroughly practical nature of the design - it is robust and not at all difficult to build. The cranks being at 90 degrees, the Engine has no dead centres. It is suitable for all kinds of stationary work at speeds up to 2,000 r.p.m. and for boats 4-ft. 6-in. to 6-ft long.

Set of Castings fully machined and with all holes drilled and tapped

Once again we are able to introduce the famous Stuart machined sets of castings. It has meant most careful preparation of tools and jigs and you will find the finish throughout is superb. Only two things are necessary to build the model :— a few files and great care to avoid damaging the machined surfaces. Then you may be sure of having a really beautiful engine.

Prices—

The Double 10 … … … … … … …£12 0s. 0d. P/Tax £2 8s 0d.

Finished engine - painted and tested:—

The Double 10 … … … … … … …£15 15s. 0d. P/Tax £3 3s 0d.

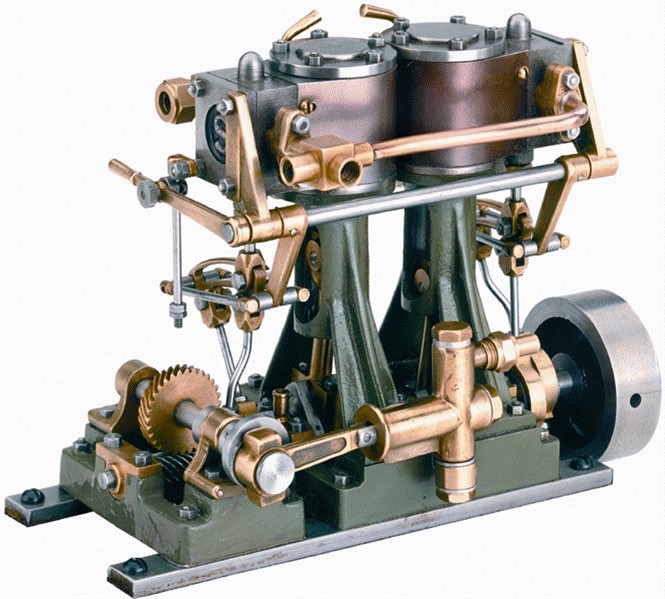

This engine has been created by making a larger boxbed and soleplate to which two No. 10v engines are bolted with a common crankshaft with cranks set at 90 degrees to avoid dead spots. Stuart proviede common steam inlet with fitting for a displacement lubricator and exhaust. The engine was available with a flywheel which requires the boxed, or a marine style daisywheel for use in a boat when the boxed could be left out. The advantage of a duplicated twin cylinder engine is that of time saving. The most time spent machining parts is setup of the part ready for the cut, with a duplicated twin once setup and michining the first part has been completed, it is a simple matter to swap in the second part.

Originally extras were limited to the drain cocks, but over time this has become one of the most accessorised engines. The first to come was the Stephenson's reverse gear, two sets of No.10v reverse gear were combined with a long connecting shaft to join the two actions. The next extra was the gear driven boiler feed pump. Mounted on a No.10v soleplate with one of the bearings cut out to leave an open side. The pump base is mounted in line with the crankshaft. An extension to the crankshaft is mounted by drilling out the end of the crankshaft for a pin to be fitted onto which an extension is mounted, on this is fitted a pre machined worm gear. On the two trunk mounting surfaces are fitted cast brass bearings to take the paired gear at 90 degrees to the crankshaft extension gear. At the end of this gears shaft is fitted a crank disk with a connecting rod that runs a pump fitted to elongated bolts that hold the nearest standard to the engine soleplate.

Please Consider Making a Donation