- © 2018 Steve Allen Contact Me 0

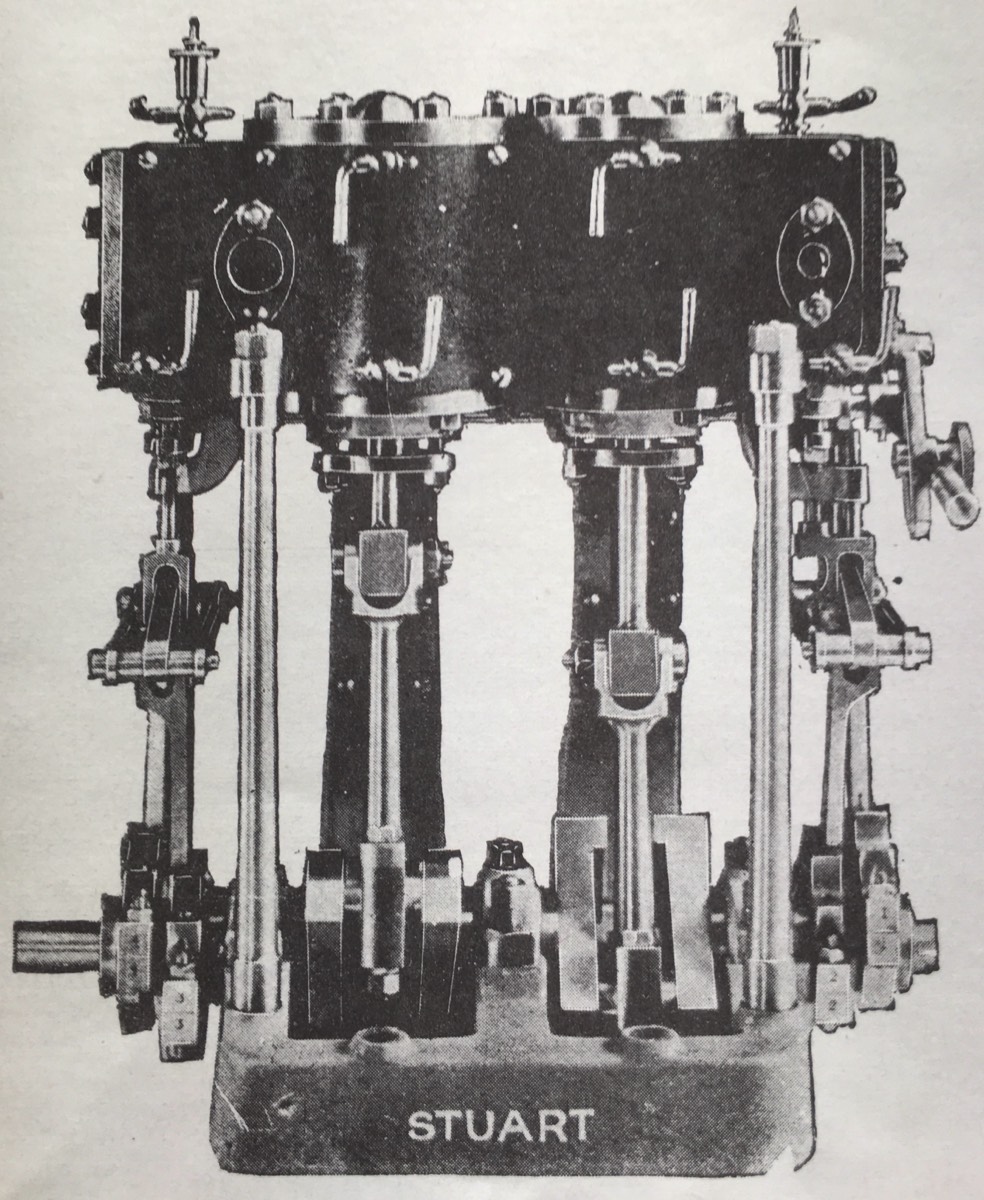

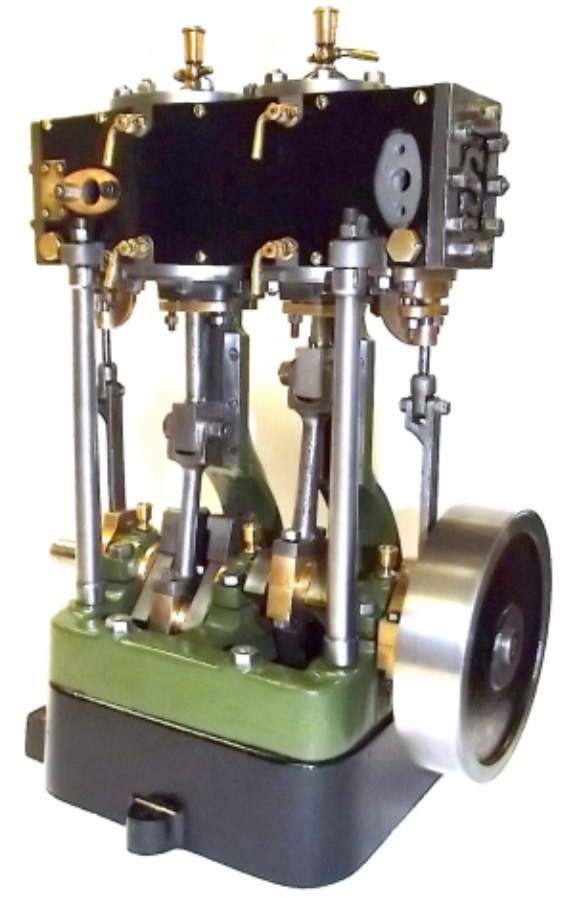

No.3

Compound

1 1/2 in. and 2 1/4 in. by 1 1/2 in. Stroke.

Finished Engines

prices :

Without Reversing Gear but mounted on Box Bed complete with 7 1/4 in. Fly-wheel or 5 in. Disc,

£12 0s. 0d.

With Reversing Gear and Disc Wheel,

£15 10s. 0d.

List of Castings and Parts.

CAST IRON.-Cylinders and Valve Chests in one casting, with steam ports cast in, 4 Pistons, 2 Ring Castings, 2 Covers, 2 Bottoms, 2 Valve Chest Doors, 2 Slide Valves, 2 Standards, 1 Sole Plate, 1 Box Bed, 1 5in. Disc Wheel or 1 Flywheel 7¼in. by ⅞in., 4 Crank Counterbalance Weights, 2 Eccentric Sheaves.

Gun-Metal.- 2 Valve Stuffing Boxes, 2 Valve Glands, 2 Piston Glands, 2 Valve Rod Guides, 2 Pairs Eccentric Straps, 4 Connecting Rod Brasses, 6 Main Bearing Brasses, 4 Flanges, 2 Valve Nuts.

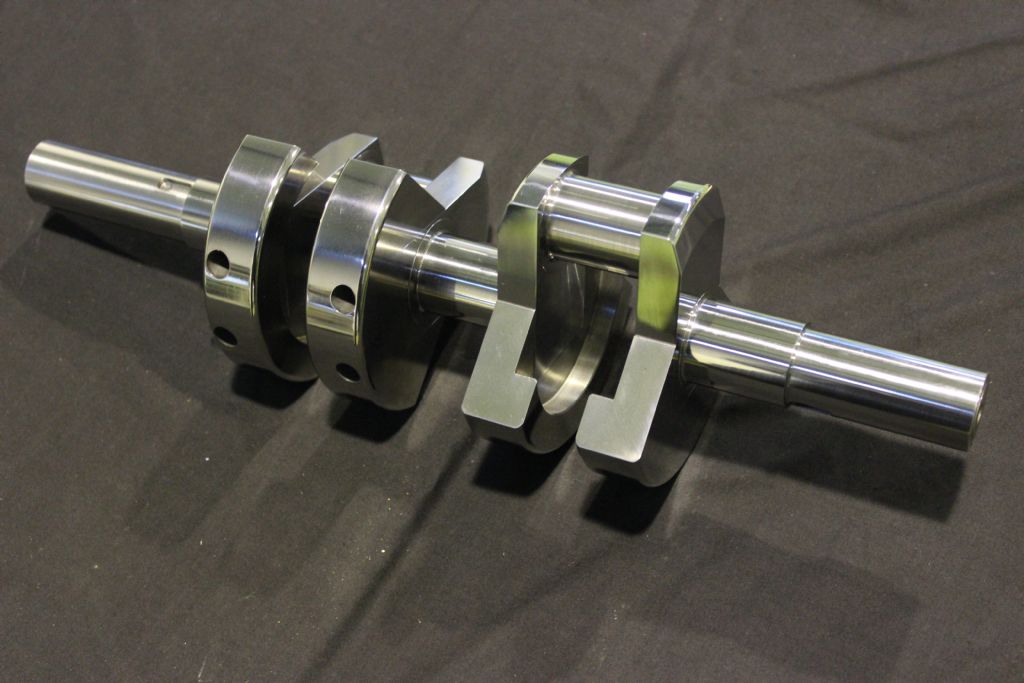

Mild Cast Steel.- 1 Crank Shaft, 2 Connecting Rods, 2 Eccentric Rods, 3 Main Bearing Caps.

Forged Steel, etc.- 2 Piston Rods with Crossheads, 2 Front Columns, 2 Valve Rods, 4 Guide Plates, Steel for Valve Rod Heads and Crosshead Bolts, Sheet Steel for Lagging, Copper Tube for Eduction Pipe.

Drawing..- A large sheet with every part fully dimensions is included.

Price, including Packing and Delivery an Henley, G.W.R. ... ... 45/-

=====================================================================

EXTRAS

All Studs,Bolts, Nuts, Screws, etc.- over 250 pieces - price 20/- Reversing Gear Castings and parts, with the necessary Studs and Nuts, etc... including full size Drawing, price 15/- Phosphor Bronze Standards, 3/6. extra Large Belt Fly-wheel, 7¼ by 1½in. ., price 2/- extra. Six drain cocks, 2 Lubricators, 12/6.

Twin Cylinders 2¼in. diam, are now supplied for these engines if required, price 2/6 extra.

The stroke of the No. 3 engine can with advantage be increased to 1¾in. in which case a forged steel crank shaft roughly machined to overall dimensions, can be obtained, price 3/6 extra.

––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––

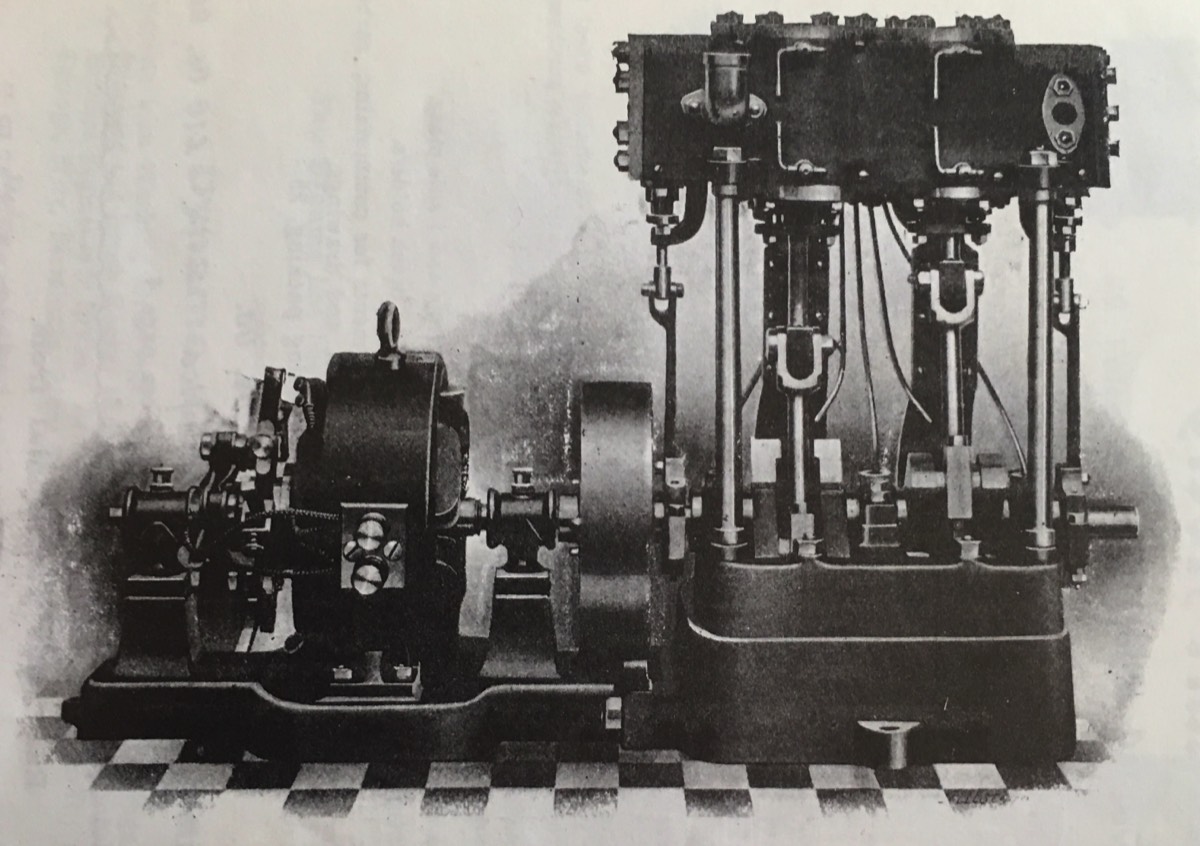

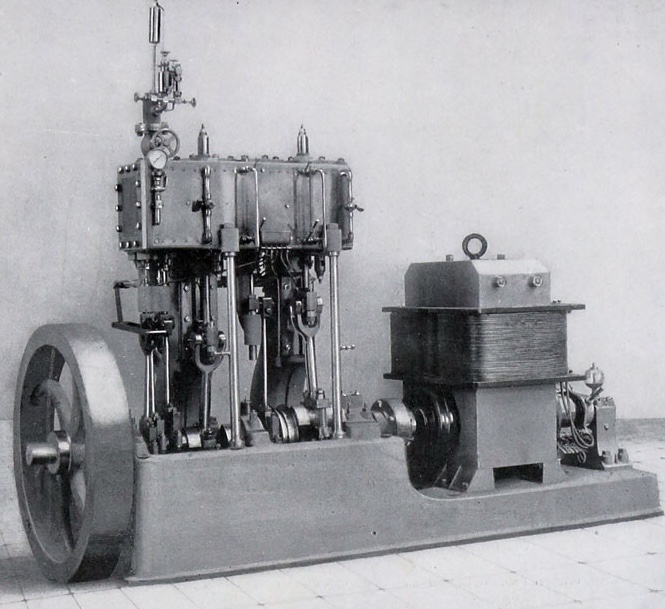

This is the next evolution of the No.1, the twin cylinder version. So many parts are the same I will concentrate on the differences. Following real engine practice a twin cylinder block was mounted on top of 2 No.1 standards and rods. The cylinder block is a compound type with one smaller diameter high pressure cylinder and a larger diameter low pressure cylinder. Valve chests and steam passages have been cast into the block requiring only valve chest covers. (called doors in the description) New cylinder tops and bottoms have been cast and some nice oilers are fitted to the valve chests, with finial lids. These lidded oilers allow oil to be added to the valve chests whilst running. A new three bearing box bed has been cast as has a new twin cylinder crankshaft with a slightly shorter throw reducing the stroke to 1½in. A new feature is the addition of cast iron crankshaft counterbalance weights. These fix to the crank web and apply weight to counteract the big end, reducing vibrations. Casting these makes construction much simpler than machining due to the radius and thinness required. Interestingly a close inspection of the catalogue photo seems to show a crankshaft with the counterweights part of the machined crank webs and not separate weights. Full size marine engines were normally fitted with counterweights but photos of engines without them are fairly common due to a tendency for them to fall off. ( nice book on marine steam engines.) A common improvement to No.1 engines is to add counterweights and paint them a nice red.

Extras are a bit more varied with this engine, starting with the standard Stephenson reversing gear. A large Belt fly-wheel is now available as this engine is capable of serious work. An interesting extra is replacing the cast iron standards with Phosphor Bronze standards. This may appear a bit odd at first but this metal has much better wearing characteristics and with the crosshead guide being machined directly into the standard this will improve wear in the long term over the standard cast iron standards. An alternate non compound cylinder block is also available as an alternative to the standard compound. A few words about compound engines. Compound engines take high pressure steam into a small diameter cylinder producing work, the exhaust steam still has a lot of energy so instead of throwing it away it is fed by an eduction pipe into a second cylinder of larger diameter producing more work. The ratio of the cylinder sizes is balanced so that they both produce the same amount of work based on the different operating pressures. The pipe between the two cylinders, the eduction pipe, is included in these calculations. As far as steam usage goes this twin cylinder uses about the same as a single cylinder engine of the high pressure cylinder size, so this should use less than the No.1. but still produce more power. However to get the best from compound engines a higher pressure is required than normally used in a non compound engine ideally superheated to reduce condensation in the eduction pipe. This pipe should be heavily lagged. The big downside of a compound engine is that if the engine stops with the high pressure cylinder at top or bottom dead center the engine will not start. It needs to be rotated until the connecting rod can exert leverage on the crank. Using the Non compound cylinder block which has a larger bore than the No.1 but shorter stroke of the No.2 means a large improvement in power and the speed of the No.2. To further up the power a Long Throw Crankshaft, increasing stroke to 1¾in, was available partially machined.

With the engine available with two seperate cylinder blocks, simple working and compound working you can choose for maximum power with self starting or steam efficiency. The two crankshafts allowed the builder to optimise horsepower with the long stroke or higher rotational speed with the short stroke crankshaft. Effectively 4 different engines. Although the Cylinder Block, Sole Plate and Crankshaft are different a lot of the castings used were from the No.1 engine.

Please Consider Making a Donation