- © 2018 Steve Allen Contact Me 0

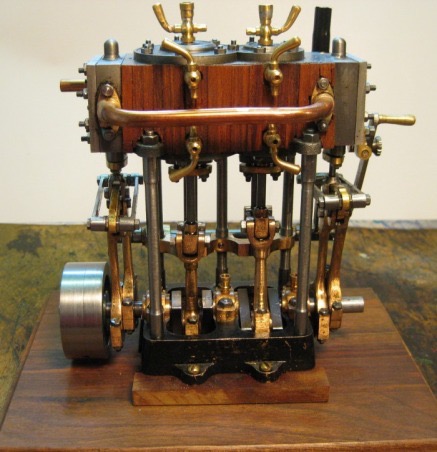

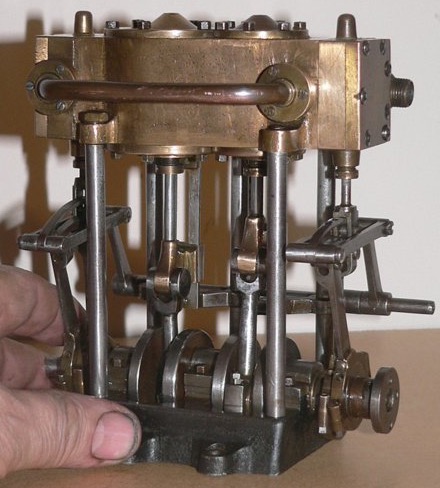

STUART

COMPOUND LAUNCH ENGINE.

3/4-in. and 1 1/4-in. Bore x 7/8-in Stroke.

Height 5 1/2-in. Overall Length 5 1/4-in. Weight 3 3/4-lbs.

With Gunmetal Cylinders 25/- Post Free.

With Cast Iron Cylinders 21/- " "

Weight packed, 7-lbs.

____________________________________

EXTRAS.

All Studs, Bolts, Nuts and Screws, price 7/- ; Four Cylinder Drain Cocks, 8/- ; Pair of Cylinder Lubricators, 5/- ; Reversing Gear Castings, Drawings and all Bolts and Nuts, 7/6.

Compound or simple, the eternal question, which is best. They both have pros and cons and its a matter of choosing which is most important. Twin cylinder simple, common 90 degree crankshaft engines have one big advantage, they will start at anypoint they stop at, so stopping or reversing dont cause any problems especially when using radio control. They also produce more power as both cylinders are connected to whatever steam pressure is available, even quite low pressure will run the engine. Steam consumption is quite high so a reasonably sized boiler is a definate requirement. Horizontal marine style boilers with low water volume and a high number of flue tubes are the best, however you will also need a boiler feed pump to feed the beast. One alternative is to use a flash steam boiler, see description below. The Compound engine is a whole different beast, as far as steam requirements the engine appears to be a single cylinder engine with the capacity of the High Pressure cylinder. As the engine only has steam feeding into one cylinder the engine can stop in a dead position that it will not restart from. To obviate this problem in a RC model, fit an Impulse Valve, see description of valves in the Pinnace Engine Sidebar. The exhaust from this HP cylinder is fed into a second Low pressure cylinder of higher volume. The ratio between the steam pressure size of both cylinders and the volume of the pipework between the two are factored into a very complex formulae to get the engine working correctly. I think I have the formulae in a book somewhere, it was way too complicated for me so instantly forgot it. Having run my Compound twin and the two I have repaired, I can say with some confidence that Stuart got it Pretty much right. So steam consumption is low but the trade off is that the engine will not run on low pressure steam. For the LP cylinder to produce work it requires a minimum pressure, the pressure supplied by the HP cylinder exhaust is lower than the HP steam input so this needs to be quite high. If you run both versions of the engine at 60-90PSI they should both produce about the same amount of work, but at lower pressures the Simple Launch should outperform the Compound. WHilst Simple engines start easier with drain cocks the compound really has to have drain cocks to get started as otherwise the LP cylinder will just fill with condensate and not warm up very fast. I have seen a drain cock fitted to the bottom of the LP valve chest to prevent the HP cylinder condensate even getting into the LP cylinder. (Seems a good idea to me.) The connecting pipe between the two cylinders should also be very well insulated. My recommendations for buying for a RC steam boat, go Standard launch engine for minimal hassle or Compound for the pleasure of overcoming the problems and being that much closer to a real boat engine.

March 20th, 1924

F.B. writes :—

"I should like to state that I am more than satisfied with the Castings and machining. I am a new customer and I sincerely regret that I have not previously made the acquaintance of your firm, which might be called 'the Model Engineers' friend.'"

March, 9th, 1924

F.J. writes :-

"The Connecting Rod is the acme of perfection and the displacement lubricator leave nothing to be desired. Thanking you for your perfect workmanship."

Please Consider Making a Donation