- © 2018 Steve Allen Contact Me 0

STUART STATIONARY BOILERS

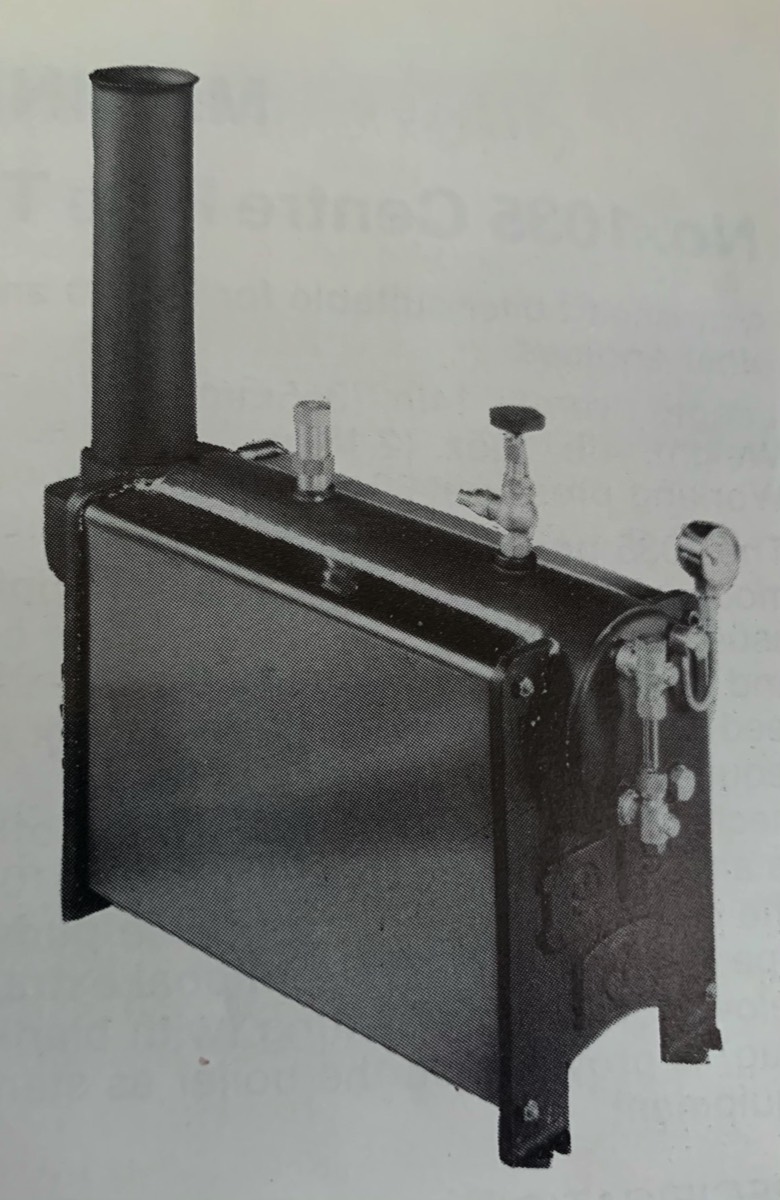

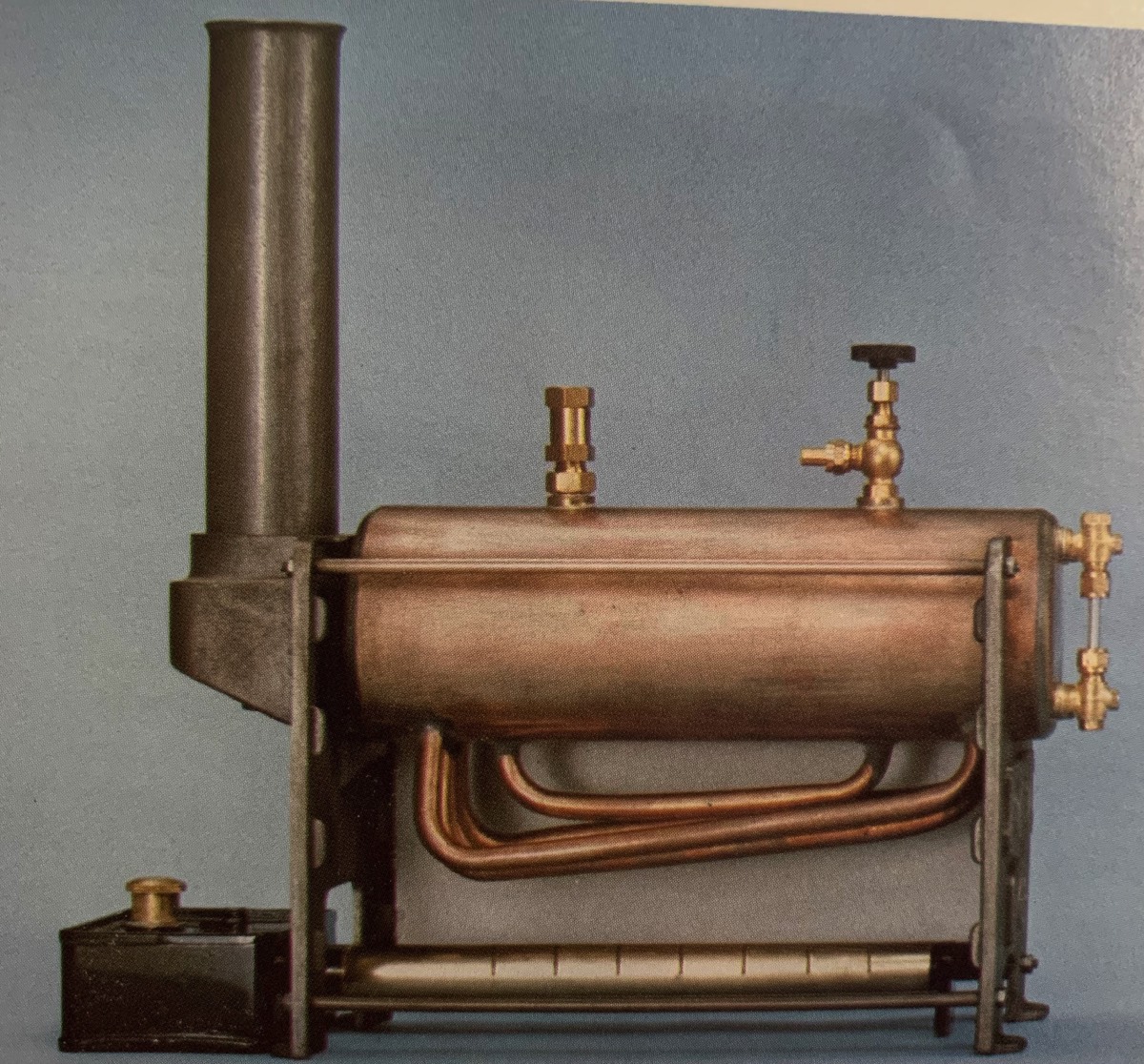

BABCOCK BOILER No. 500.

FITTED WITH SUPERHEATER.

Specially designed for steaming the Mill engine, Progress and other small engines of similar cylinder capacity.

Like the engine, it can be built without any special tools.

Complete Set of Parts, 30/-

Finished Boiler ... 40/-

Post Free

Steam pressure gauge and syphon 10/6 extra. Water gauge in place of test cocks, 2/- extra.

Foreign orders must include extra for 8-lbs. postage.

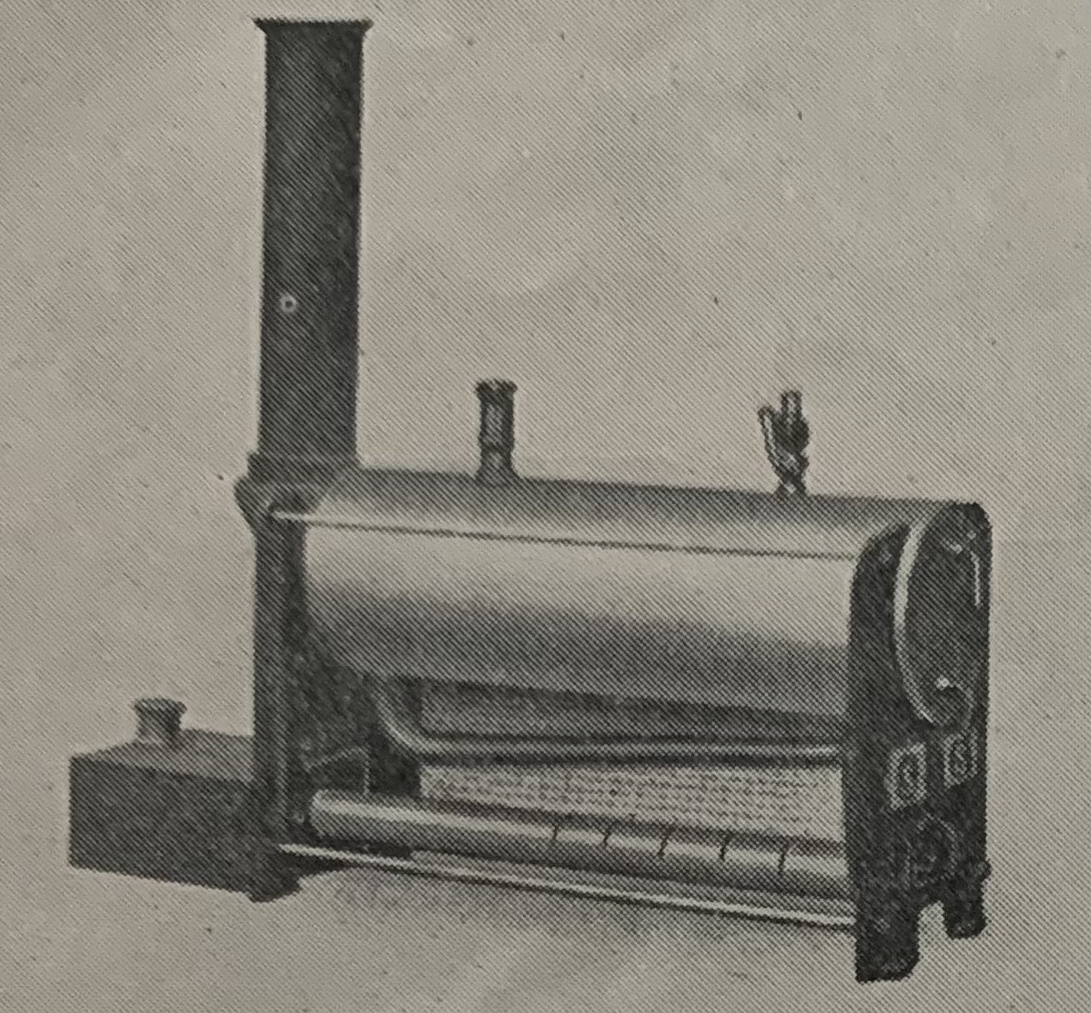

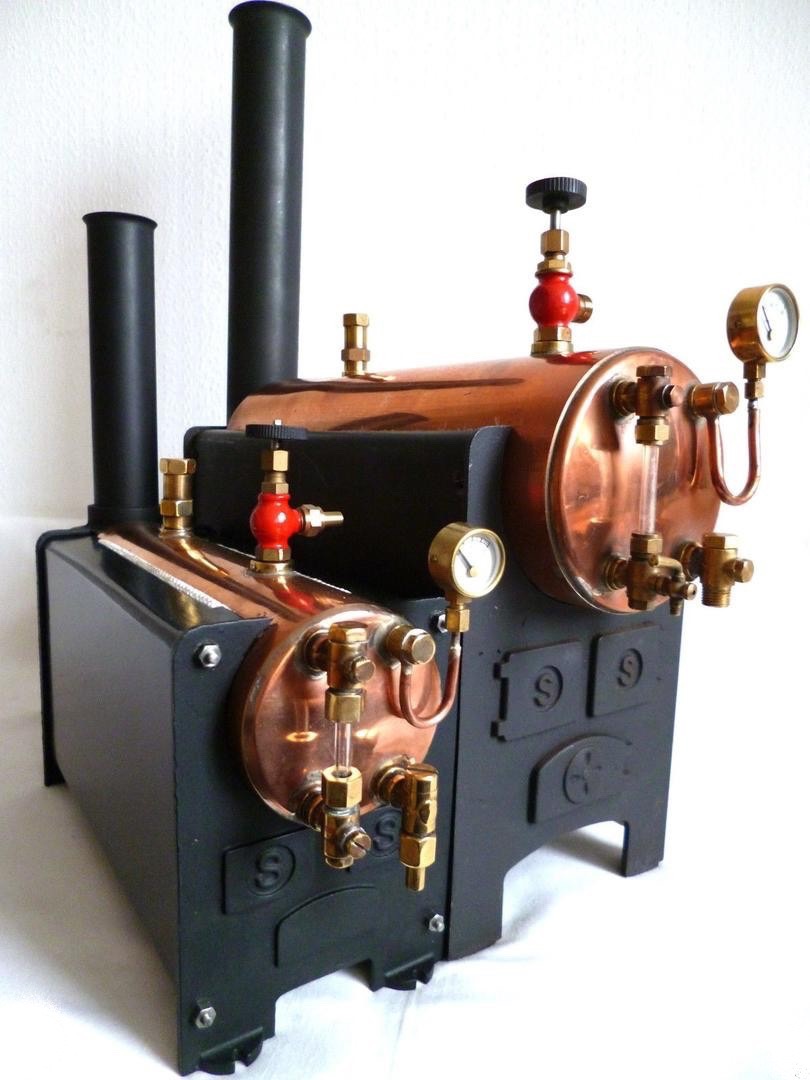

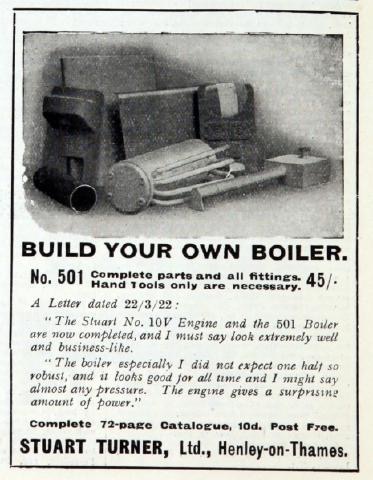

BABCOCK BOILER. No. 501.

Fitted with Superheater.

Designed on the same principle as our famous No. 10 and B.B. engines. No turning, brazing or soldering required. With hand tools a well designed and very efficient boiler can be constructed.

It has copper drum, 23-in. x 8-in. and four water circulating tubes and superheater. The front and back are cast iron, the latter carrying the chimney of steel tubing. The sides are planished iron bent to shape and lined with asbestos.

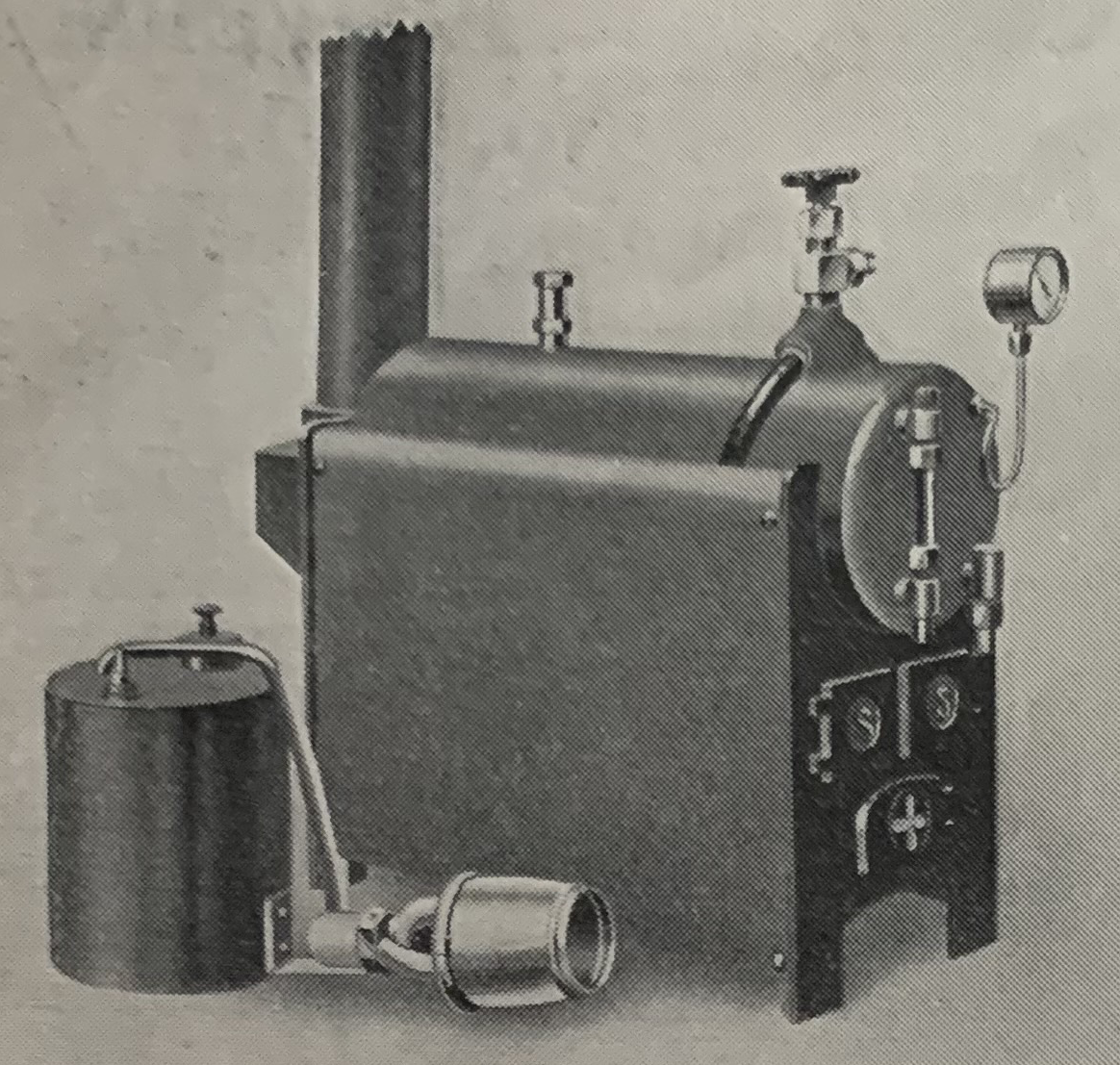

We have made many experiments with a view to providing a spirit burner more efficient than the usual type, and have succeeded in producing one that Is very simple, safe, and extraordinarily efficient. It is so designed that the spirit is vaporized and burns with a very hot flame, and it is suitable for all types of horizontal boilers (see page 68).

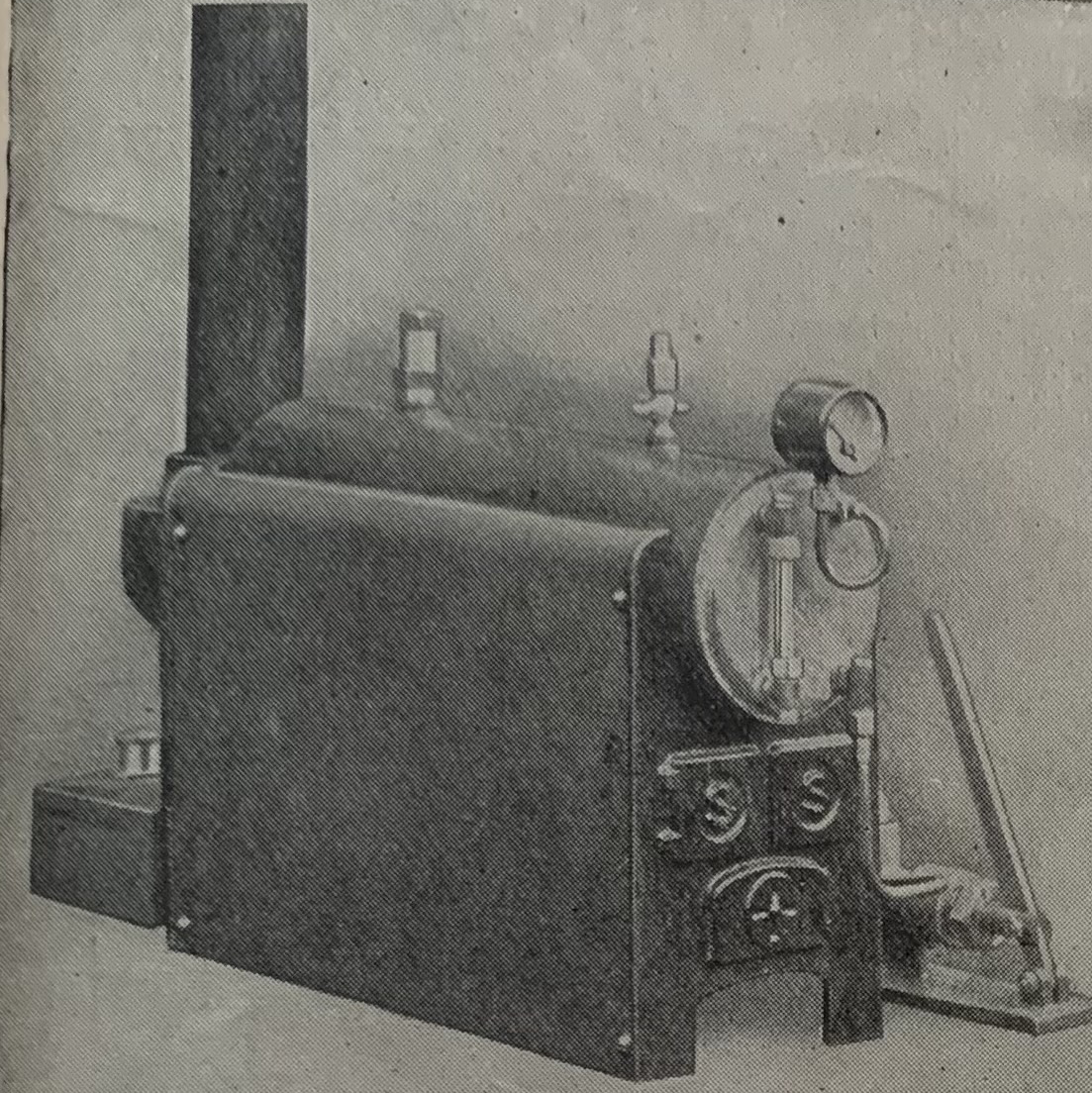

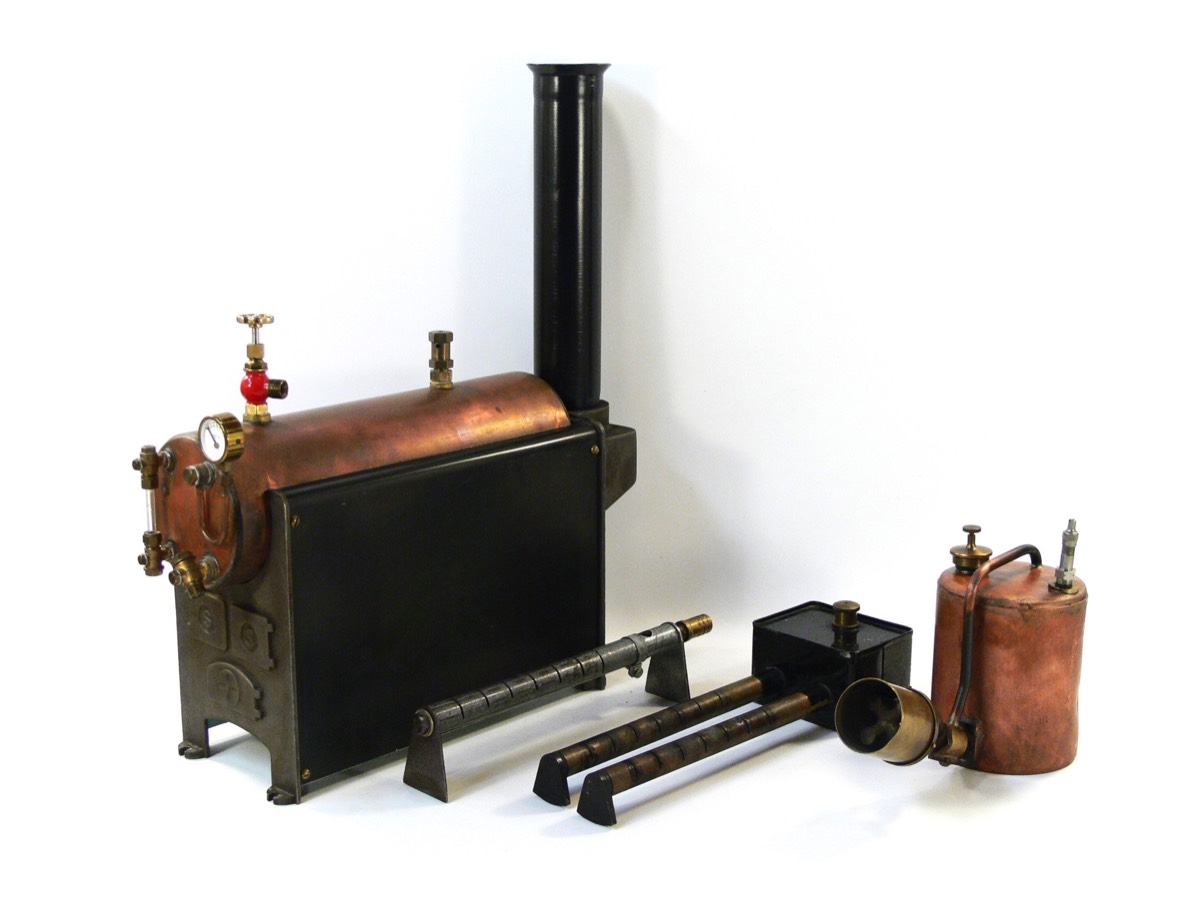

No. 504.

This boiler, a similar design to the No. 501, has copper drum 34 10-ins., 7 water circulating tubes, and superheater fitted. A paraffin lamp with special Primus burner is used, or gas if specified, It will steam continuously at full power, all engines with cylinders up to l-in. x 1-in., and should be installed when the No. 10 or B.B. engines are used for driving the “O” dynamo. Working pressure 60-lbs.

SET B. Comprising the drum with seatings for all fittings drilled and tapped, 2 cast iron ends, 2 side plates flanged to shape and drilled, asbestos lining, and fixing screws, chimney, safety valve, water gauge, and screw-down steam valve 60/- carriage paid

Foreign Orders must include extra remittance for 14-Ibs.

The basic Stuart boiler for use with static engines. The design is simple consisting of a boiler tube that is mounted in a frame. Consisting of two cast end caps one detailed like the front of a coal fired boiler with raised letters and fire hole door. The other end mounts the Chimney and has a cutout for the insertion of the burner underneath. the two sides are formed from plate steel with the long edges rolled over to fit round threaded rods that secure the two ends. A plain chimney with a slightly flanged top completes the construction. mountings are tapped for fitting a drain cock, water gauge, pressure gauge, safety valve and output valve. The 500 and 501 appear the same as their sizes are pretty much the same. However if you turn them upside down you will notice the big diference, the number of circulating tubes. the 500 has 3, the 501 has 5 and the 504 has 7. All is not as it seems. The outer pairs of pipes are regular circulation pipes designed to be angled lengthwise to create a current of heated water, however the centre pipe is different. the pipe is shorter and is not connected to the outside of the boiler like the circulation pipes. Instead is is connected to the inside of the steam outlet connection below the valve. is passes down and though the boiler wall, runs outside and then reenters the boiler and opens to the pressure right below the safety valve. so steam passes from the pressure vessel outside and through the flame before reentering the vessel and connecting to the steam output, effectivly super heating the steam. The 504 boiler had an optional extra superheater, that fitted to the outside og the boiler. A cast fairing fitted onto the steam output below the valve, pipeswork then carried the steam down the side underneath the boiler into the flame and then circled back up the other side of the boiler and uo to the control valve.(See image below and the main catalog image for the 504 above)

The white mineral heat resistant liner is made from ASBESTOS, a particularly nasty material which sheds fibres that get stuck in the lungs causing a nasty disease. Safe modern heat resistant lagging is available.

21st February, 1926.

H. C. writes :—

"Your repair to my No.501 boiler has been most satisfactory. I must honestly say that your boiler is the most efficient that I have ever met. It raises 60-lbs. in three minutes from cold, and drives my engine continuously at full throttle with a continual supply of feed water."

Please Consider Making a Donation