- © 2018 Steve Allen Contact Me 0

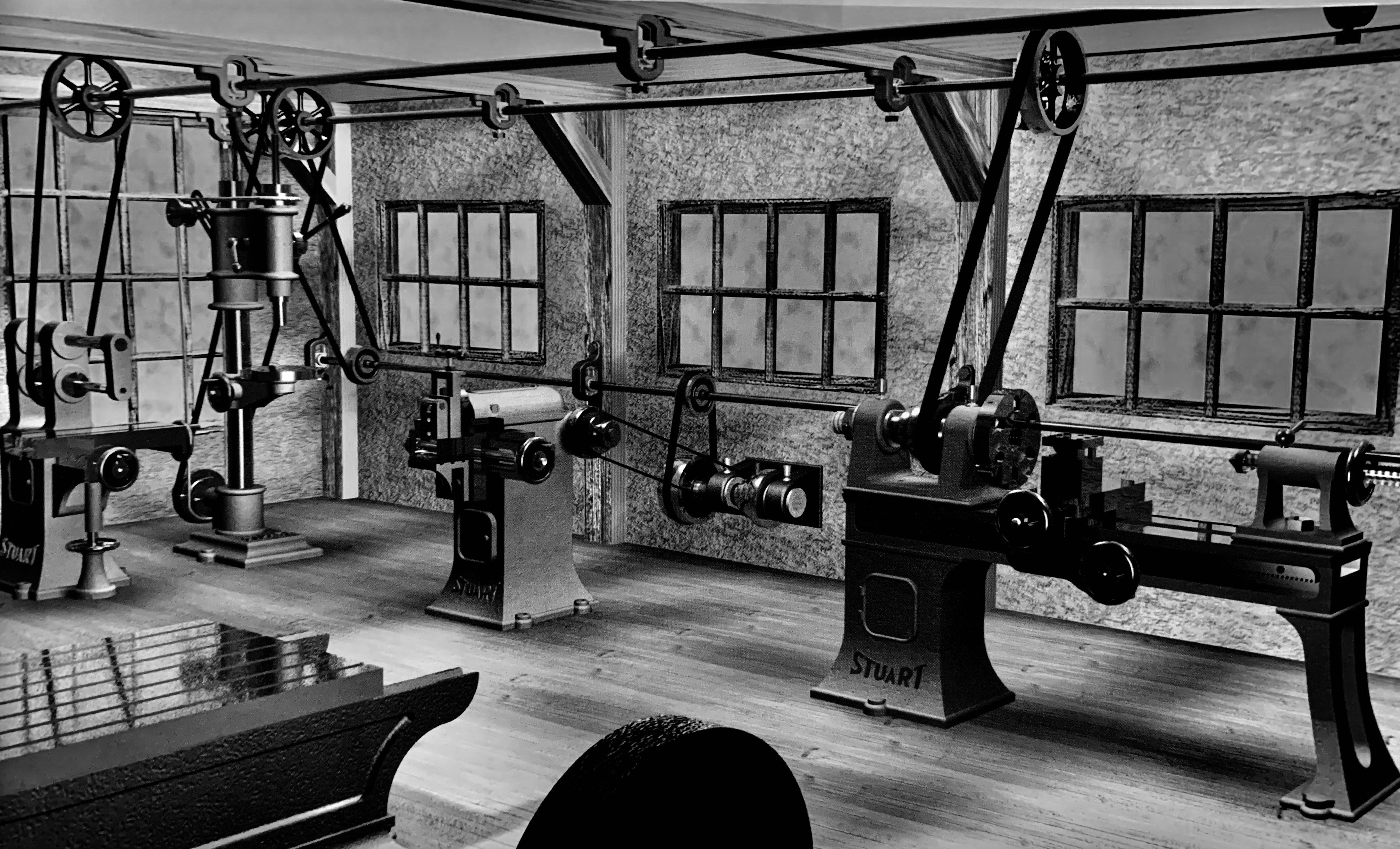

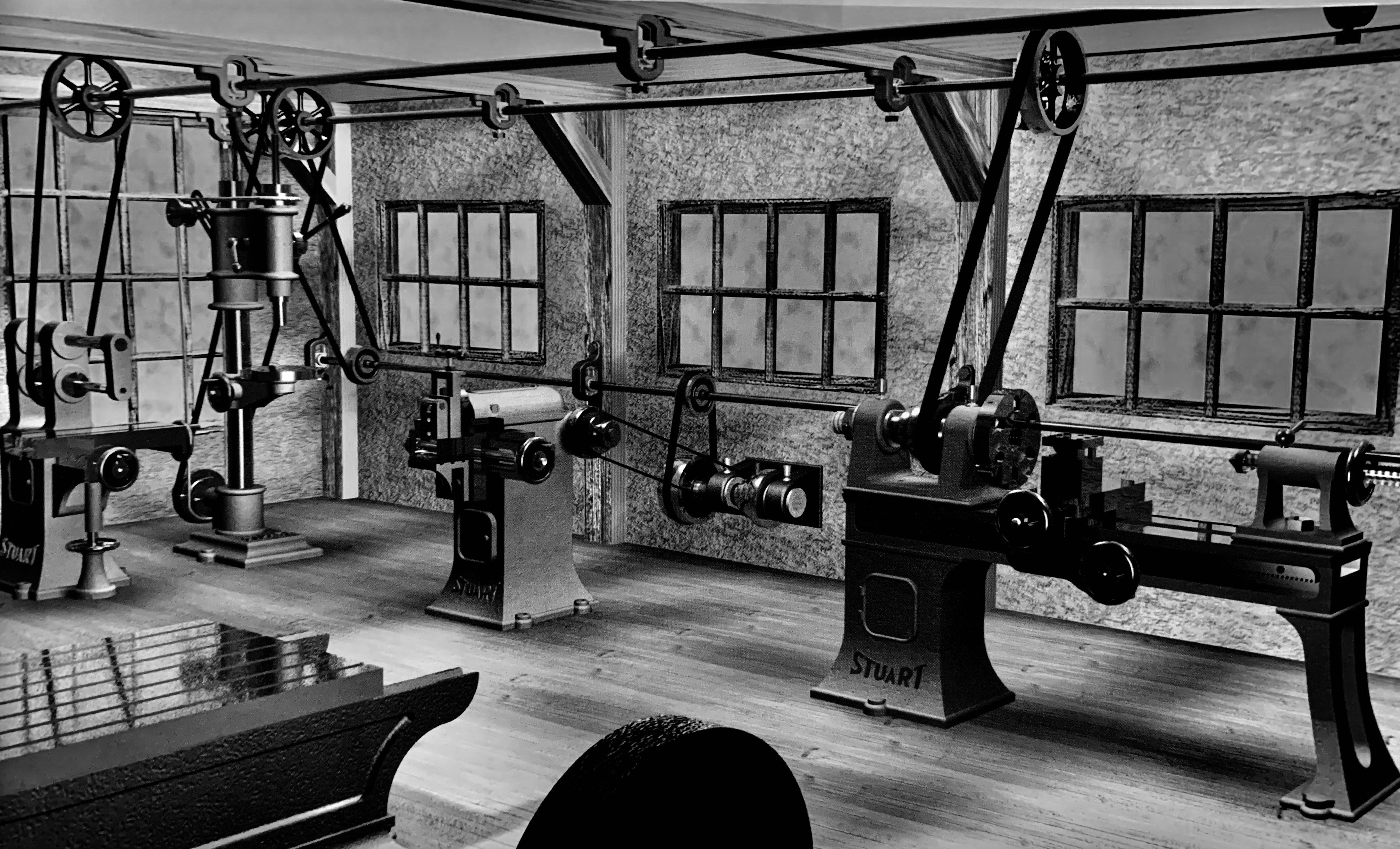

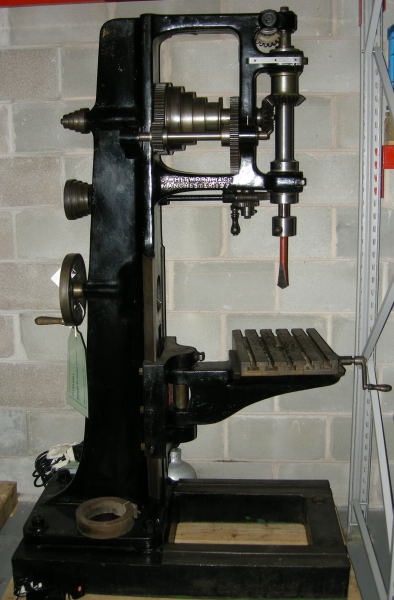

Pillar Drill

Height 9 1/2 in.

As with the rest of our range of workshop machines the Stuart Pillar Drill comes complete with pre cut gears, making machining considerably easier.

The Pillar Drill has a rising table operated by a rack and pinion mechanism, in the same way as full sized machines of the period were operated. A choice of running speeds can be selected by utilising the stepped pulley.

CONTENTS

Cast iron - bed, tail stock end base, head stock end base, head stock, pulley.

Brass - Bushes.

Steel - Spindles, spindle nuts, face plate, four jaw chuck assembly, saddle assembly, tool post assembly, cross slide assembly, tail stock assembly, rolling centre, handles, hand wheels.

Sundries - Detailed drawings, fixings pack, finished gears.

This is a pretty scale model of an old pillar drill as found in workshops, powered by overhead shaft and belt drives. The belt drive is at the bottom rear and has three speeds. drive from this is by a sprung band up and over two pulleys to the top drive for the drill spindle. The drill quill is raised and lowered by a control handle just like the real thing, acting against a small spring. A very small drill is secured in the bottom by grub screws. The image show a plain fixing but I have seen examples where a drill chuck has been fashioned for a more scale look. The table can be unlocked and a wheel winds it up and down via a gear rack mounted in a slot machined into the pillar. All in all a very nice model and quite rare to find.

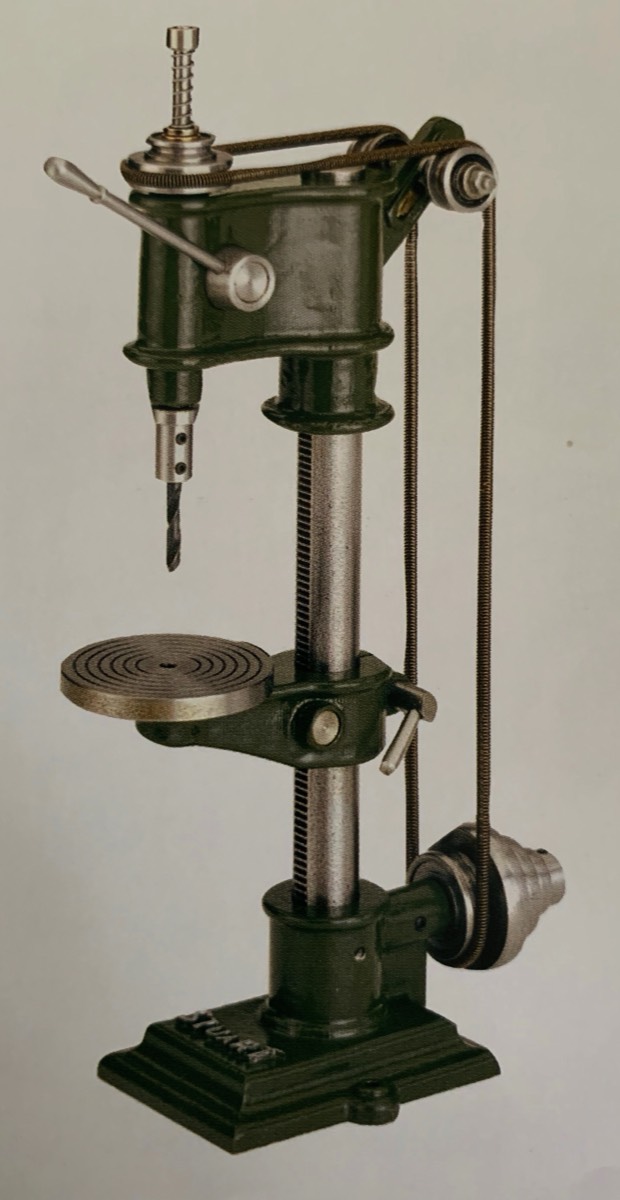

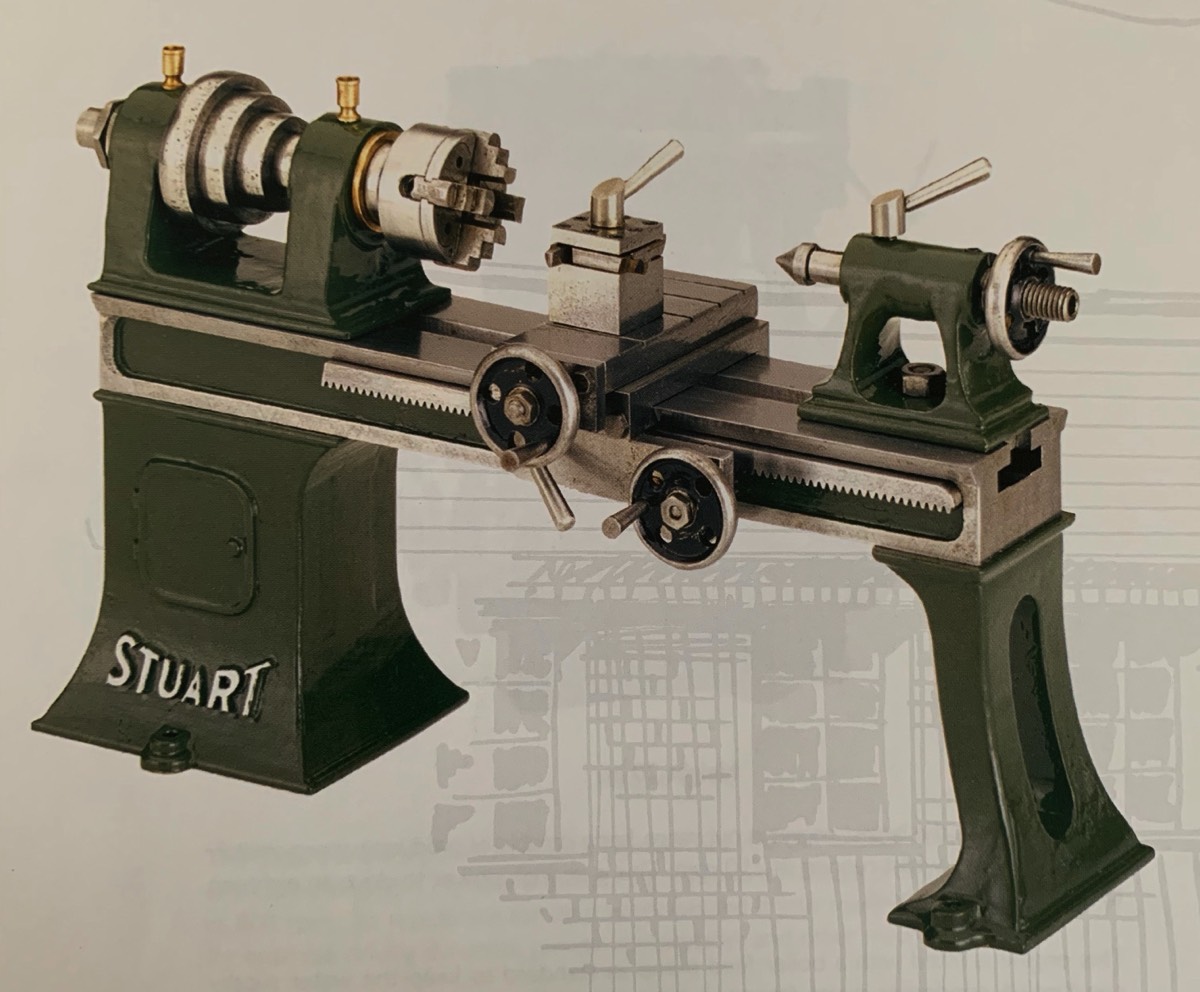

Engineering Lathe

Length 8 1/2 in.

The Stuart Engineering Lathe has been carefully designed by taking the most interesting elements from lathes in use at the end of the 19th century and combining them to produce an attractive model.

As with the rest of the workshop machine models the Engineering Lathe can be successfully powered by any of our engines from the Stuart S50 upwards.

CONTENTS

Cast iron - bed, tail stock end base, head stock end base, head stock, pulley.

Brass - Bushes.

Steel - Spindles, spindle nuts, face plate, four jaw chuck assembly, saddle assembly, tool post assembly, cross slide assembly, tail stock assembly, rolling centre, handles, hand wheels.

Sundries - Detailed drawings, fixings pack, finished gears.

Another well designed scale replica of a real machine. The base castings are neatly styled and connect to the lathe bed. The head end base is large and easily machined, however the tail end support is an akward shape and mounting for machining appears to be problematic. I have heard several cases of the casting breaking whilst machining. Take great care supporting the end being machined. The lathe bed, like the full size lathe, is a complex shape. But unlike the real thing the shape is entirely machined as opposed to cast. This means that quite a few accurate milling processes are required. Top, bottom, ends, sides, t slot, dovetail sides, reccess for rack, etc… The tailstock casting is nice and require a few accurate machining processes. The nut to hold it in place stands out as being a bit naf, so maybe creating something a bit more appealing would be worth the effort. The Heasdstock is machined out to take brass bearings that support the spindle, machined with different pulley sizes to provide different working speeds. The Spindle is machined to allow diferent attachments. A faceplate with mounting holed is detailed in the drawings as well as a four jaw independant chuck, probably the most complex single assembly of any of Stuart's kits. I have seen a couple of variations on models so some keen engineers have deviated from the plans for a simpler or more accurate chuck. I have yet to see a three jaw self centreing chuck, so masochists out there, that would be a challenge. The rack is provided premachined as are the gears of the carriage. This is another complex assembly that requires the main part to be carved from a single block, requiring a lot of material to be removed, I wonder if it would be easier to construct the main item from separate parts to ease construction. The cross slide is machined with fake T slots for appearance and mounts a standard square rotating toolpost. The handwheels are simple disks perforated with holes and fitted with a peg for faster rotation.There is also fitted a lever to lock the carriage to the rack to prevent movement. Another very rare Stuart Model.

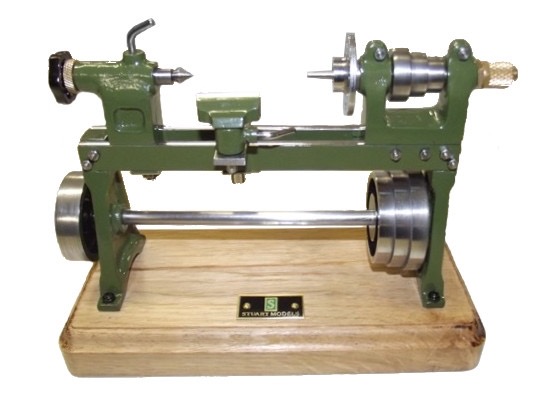

Wood Turning Lathe

Length 8 1/2 in.

The Stuart Wood turning Lathe has been carefully designed by taking the most interesting elements from lathes in use at the end of the 19th century and combining them to produce an attractive model.

As with the rest of the workshop machine models the Wood turning Lathe can be successfully powered by any of our engines from the Stuart S50 upwards.

CONTENTS

Cast iron - bed, tail stock end base, head stock end base, head stock, pulley.

Brass - Bushes.

Steel - Spindles, spindle nuts, face plate, saddle assembly, tail stock assembly, rolling centre.

Sundries - Detailed drawings, fixings pack, finished gears.

Yet another quality workshop machine, this time a wood turning lathe. The design is substantially different from the engineering lathe. The main structure consists of two cast end stands bolted together by the bed which consists of two steel bars in parallel. The headstock is bolted to one end, The main spindle has 3 pulley sizes for variable speed operation, with a belt picking up drive from the matching pulleys below connected by the drive shaft to the main drive belt pulley at the tail end. Slipping the speed belt from one pair of pulleys to the another allows 3 speeds for the spindle. A wood turning faceplate with spike is fitted. A tool rest is fitted to the bed in the middle and can be moved backwards and forwards.

Shaping Machine

Height 6 1/2 in.

The Stuart Shaping Machine faithfully reproduces the design of single crank shapers that were still in use well into the mid 20th century.

Che clapper box can be raised and lowered to adjust the amount of material being removed in the same manner as the full sized machines.

Contents - Iron Castings, Bar Stock, Fixings and Drawings

Drive is, like the others, via a three stepped pulley. This drives a crank hidden inside the main casting. The crank drives the reciprocating head that is fitted at one end with the cutter. The cutter is mounted on an adjustable, vertical slide. The cutter is mounted in a freely pivoting mount, this allows the cutter to cut as the head moves out, with the cutter pushed against the slide. on the return stroke the cutter flips up out of the way. Work is mounted on the workstand, this is grooved to simulate T slots. This is fitted on a horizontal, adjustable slide. It is not possible to mount a piece of work on the workstand due to the fake T slots. Hovever I have come accross a model where the machinist had mounted a piece of work by using a hidden bolt up through a hole drilled in the workstand. It looked very convincing and the cutting tool would actually cut a groove into the workpiece. The only thing missing from the real thing is a feeding device to move the work slides.

Vertical Milling Machine

Height 7 in.

The Stuart Vertical Mill takes advantage of being directly driven by bevel gears to the spindle. This allows for a greater transfer of power to the tool.

The model is based upon the older style of milling machine and does not include any mechanism to raise and lower the tool, instead this is done entirely using the table.

CONTENTS

Cast Iron - Body, head, jacking column, knee, pulley.

Brass - Bushes.

Steel - Lead screws, shafts, jacking wheel and screw, cross slide assembly, table assembly, locking screw, saddle, spindles, handles, handwheels.

Sundries - Detailed drawings, fixings pack, finished gears.

The main body is constructed of two castings, a base and head. The head holds the stepped pulley allowing different driving speeds and the bevel gears that drive the vertical chuck. The base unit is machined with a dovetail to mount a vertical slide controlled by an adjustment wheel at the bottom, this is called the Knee. In early milling macines the engineering to allow vertical movement of the head was complicated and so the height of the work bed was made adjustable instead, much cheaper. Mounted to the Knee are a slide to position work forwards & backwards and a cross slide to position the work left & right. The cross slide top has fake T slots cut into the surface.

Horizontal Milling Machine

Height 5 3/4 in.

The Stuart Horizontal Mill follows closely the design of machines used in workshops and factories throughout the late 19th and early 20th century.

We are able to supply the model as either a full set of castings with all the materials, fixings and drawings needed to finish the model or as a machined kit ready for assembly, or as a finished model ready to run.

CONTENTS

Cast Iron - Body, jacking column, knee, pulley.

Brass - Bushes.

Steel - Lead screws, shafts, jacking wheel and screw, cross slide assembly, table assembly, locking screw, saddle, spindles, handles, handwheels.

Sundries - Detailed drawings, fixings pack, finished gears.

The main body is a single casting unlike the Vertical mill. At the top it mounts the stepped pulley ahis is on the same spindle as the cutting disk. Above is mounted a support bar and casting tuo support the end of the spindle. This would be removable to allow fitting of different cutting tools.A Knee is fitted to allow height adjustment of the working surface and a slide and crosslide to control the in / out , left / right movement of the surface plate. Fake T slots are machined into the surface plate. It is not entirely obviouse but this machine si significantly shorter than the vertical mill. I had assumed that the two mills would use a common main casting with different top castings. It appears that the vertical mill is split into two casting to keep the casting size down.

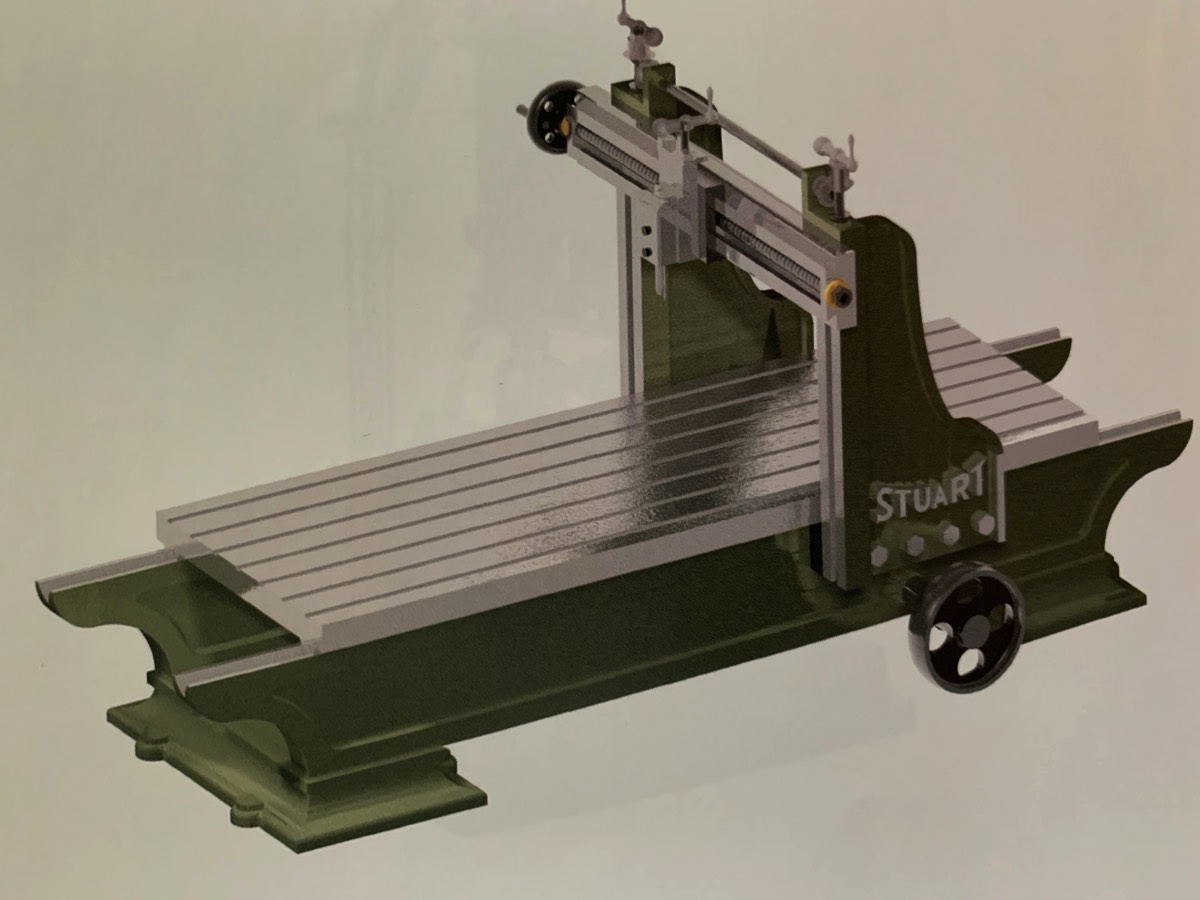

Planing Machine

Length 13 in.

The Stuart Planing Machine is the largest of the models in the range of workshop machines, and would make a fine centrepiece to any workshop set up/

The set of castings comes complete with finished gears which simplifies what can otherwise prove to be a difficult job even assuming access to the correct machinery.

Well this is an unexpected adition to the workshop. I hadnt seen one of these before I did some research. The name makes it sound like a woodworking Planing machine. The name is a bit misleading, it is in fact a Shaping machine designed to allow work on large objects. Real worldlaning machines can accomodate work 10-15 feet or longer. It is not immediatly apparent that the work table slides backwards and forwards controlled by the handwheel on the front. On the full sized machine, a reciprocating drive would be installed to move the table backwards and forwards. Another device would increment the cutting head to allow deep cuts or wide cuts. Check out the video. I have no photos of the kit unmade so this is from appearance. There appear to be 2 base castings, 2 side castings a work table casting, 2 castings for the raised sides. the rest appears to be constructed from material.

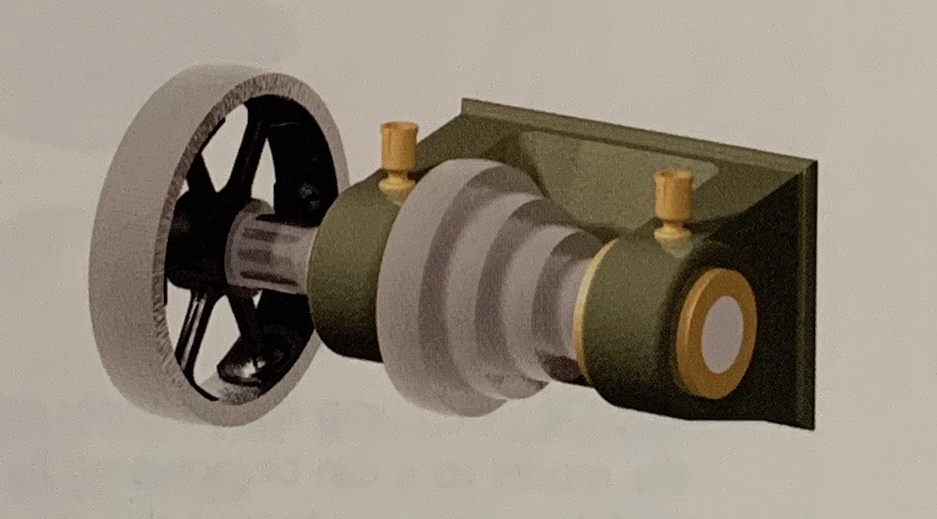

To allow modellers to build a fully working workshop Stuart created a range of extras. All the bits needed. I have included below sample items but for example there were 4 different sized puleys available.

Please Consider Making a Donation