- © 2018 Steve Allen Contact Me 0

"PROGRESS" SETS.

The Progress Sets of model engine castings are intended for those who have the use of a small lathe. The progressive character of the design is perfectly thought out from both an educational and constructional point of view.

The castings are the best of their respective materials, and the sets are complete with all screws, shafts, rods, drawings and instructions. The most difficult part of the work-the boring and facing of the cylinders is already accomplished. No other machining is done.

The first two models are of oscillating-cylinder engines the others are of various types representing (1) the short stroke, high speed, horizontal engine (2) the vertical or marine engine (3) the long stroke Mill," engine (horizontal), and (4) the self-contained Undertype engine and internally-fired high pressure boiler. Boiler parts are supplied separately, and these, when finished, will make a generator sufficiently powerful to maintain steam in any one of the models.

Of course, being of small dimensions, purchasers must not expect them to be capable of accumulator charging, lathe driving, We supply other sets for such purposes.

They are sufficiently powerful to drive the Stuart Dynamo and light one lamp.

NOTE.

All bolts are included : cylinders are bored and faced, and the shafts, piston and valve

rods, studs, etc. are screwed, thus no stocks and dies are required. Fittings are not included : the price of these will be found in our general catalogue.

With each Set is a handbook giving minute detailed drawings and sketches.

This book, which will be very useful to many amateurs, may be purchased separately, price 7d. post free.

These Sets are intended for the student in Steam Engine practice, and we cannot

undertake machining separate parts

☞ FINISHED ENGINES ARE NOT SUPPLIED ☜

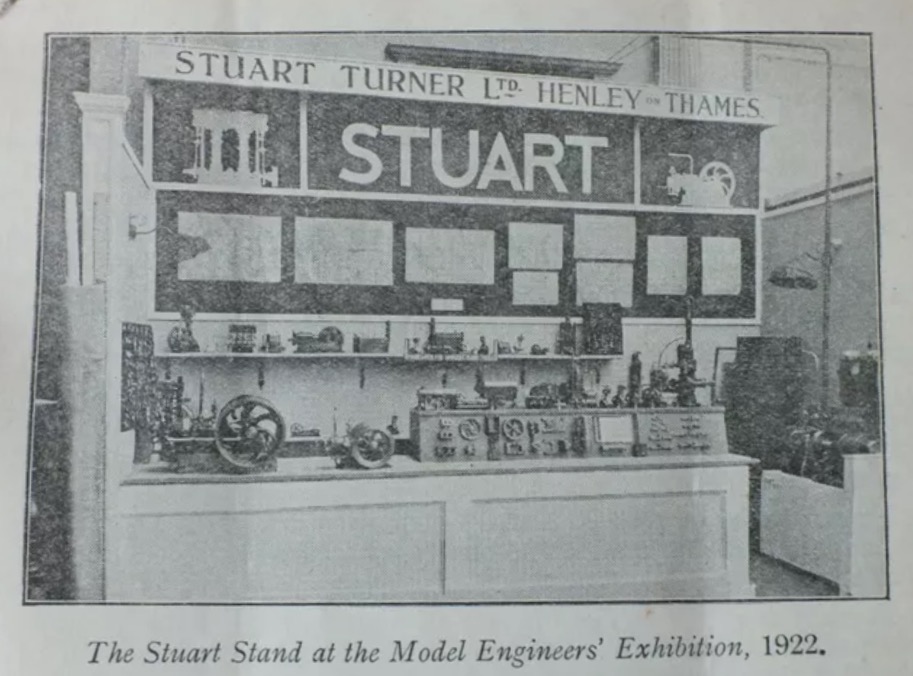

O.H. OSCILLATING HORIZONTAL ENGINE.

1/2-in. bore, 3/4-in. stroke, all castings in best gunmetal and box bed and flywheel in iron, complete with

crank and piston rods, and all studs, nuts and bolts.

Price, 9/- Post Free.

Weight packed, 2-lbs

These are the simplest form of Double-acting Steam Engine, and the student should build either of these with a view to learning the peculiarities of the method of distribution.

O.V. OSCILLATING VERTICAL.

1/2-in. bore, 3/4-in. stroke, in best gunmetal and disc wheel in iron, with crank and piston rods, all studs, bolts and nuts.

Price, 7/6 Post Free.

Weight packed, 2-lbs.

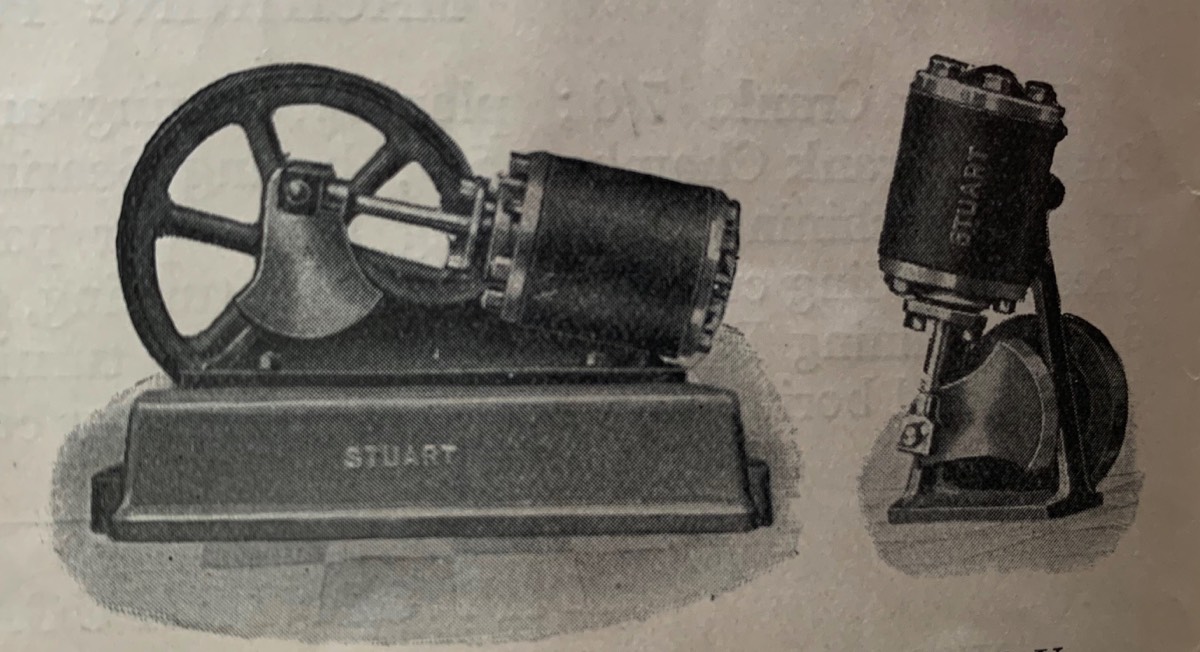

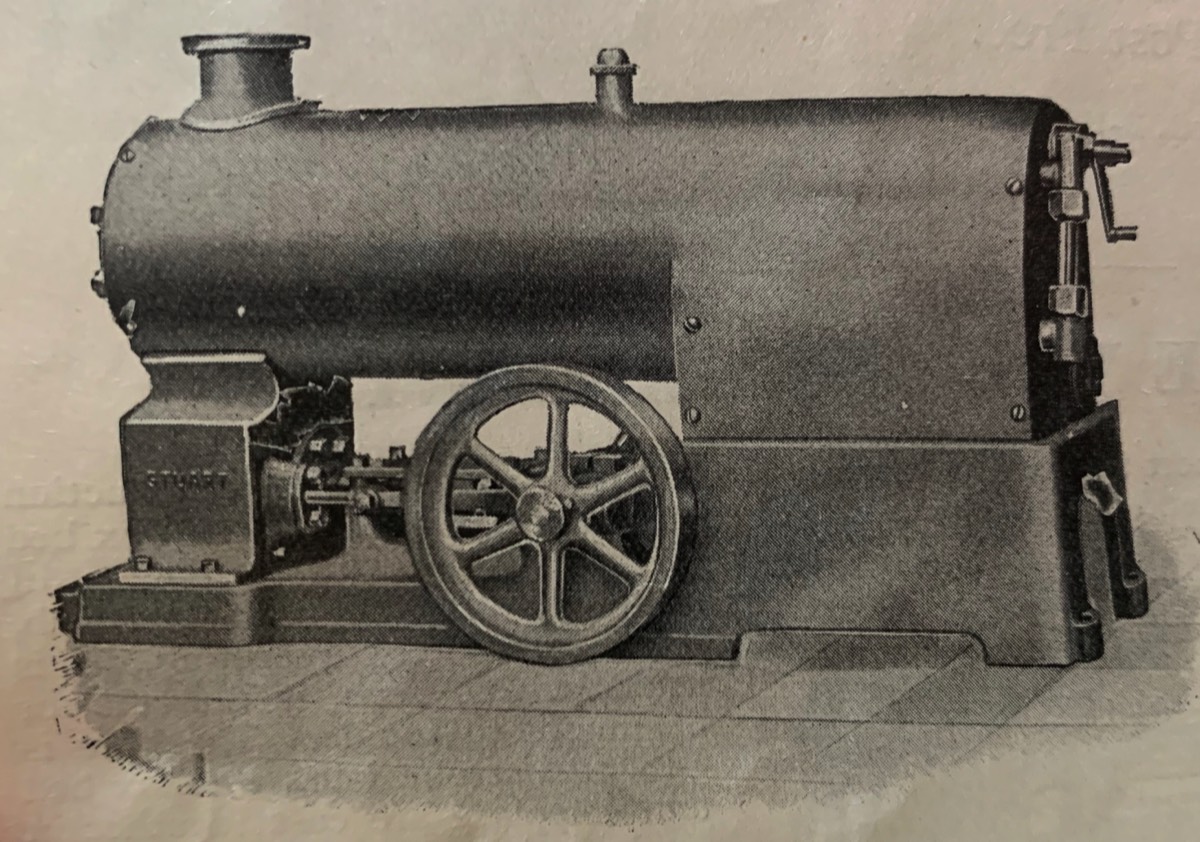

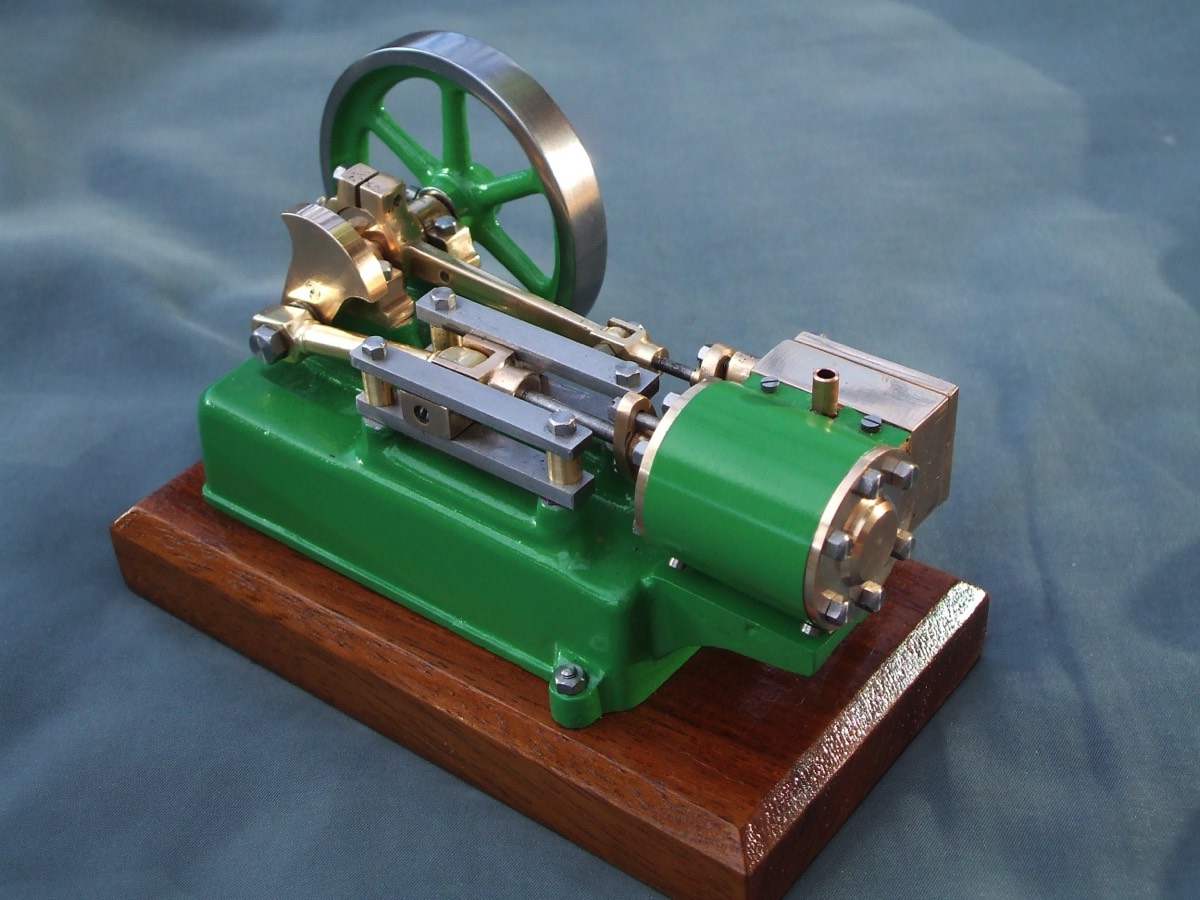

H.U. HORIZONTAL UNDERTYPE.

Price 27/6 (Weight packed, 7lbs)

Post Free.

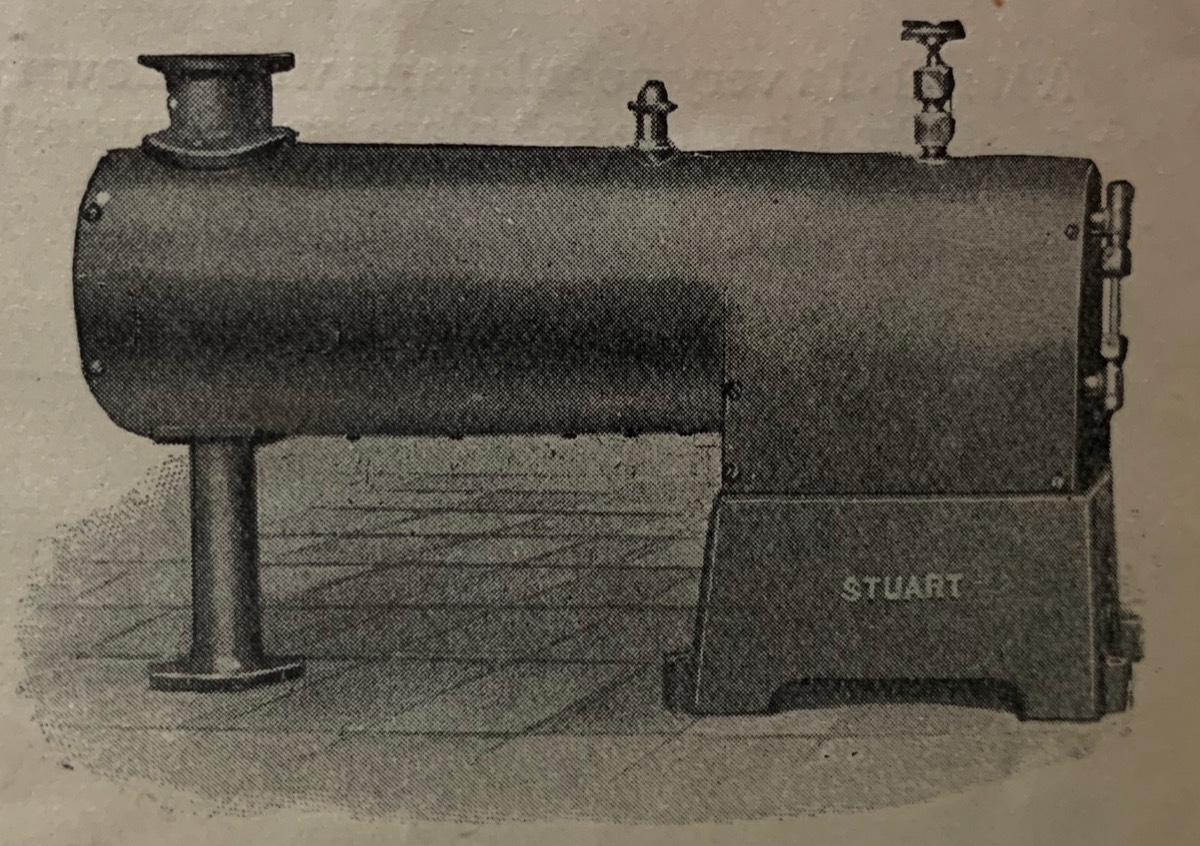

L.B. LOCO BOILER

Price, 12/6.

Post free. Weight packed, 4lbs.

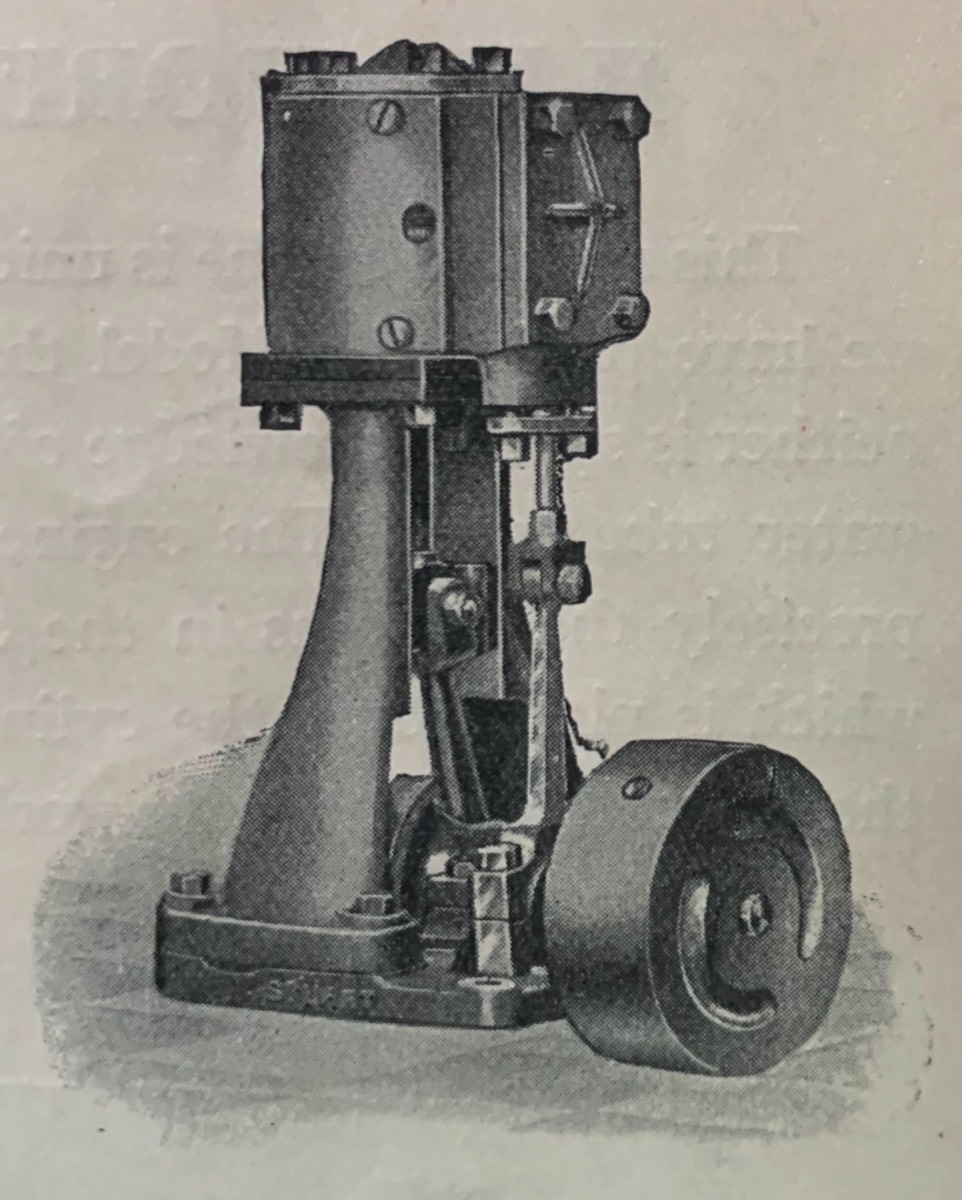

S.V. SLIDE VALVE

VERTICAL.

A very pretty model of a Single Cylinder Launch Engine, bore 1/2-in,. Stroke 3/4-in. All casting except the disc wheel which is in Iron, are of best Gunmetal. The set the more advanced students, it is however a very smart model, and since it is capable of being polished throughout, is one that will appeal to model makers for exhibition purposes. The set is complete with crank, piston rods, and all studs, nuts, bolts, etc.

Price 10/6 Post Free.

Weight packed, 2 lbs.

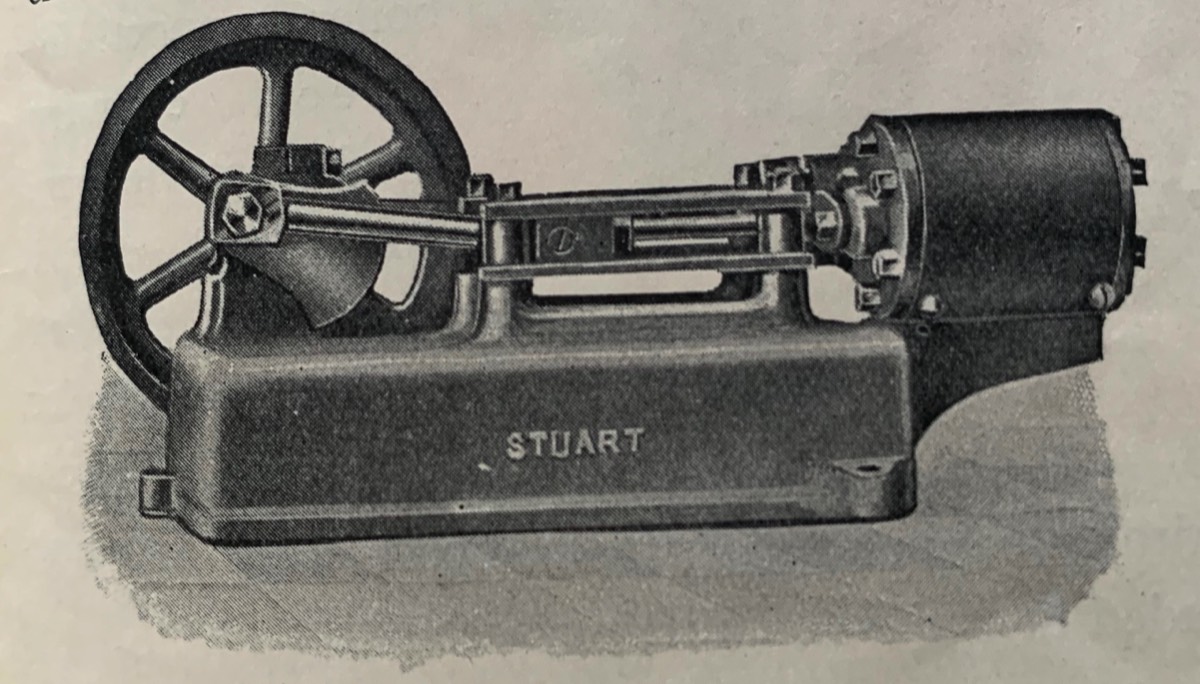

S.H. SLIDE VALVE HORIZONTAL.

Price, 10/- Post Free.

Weight packed, 3-lbs.

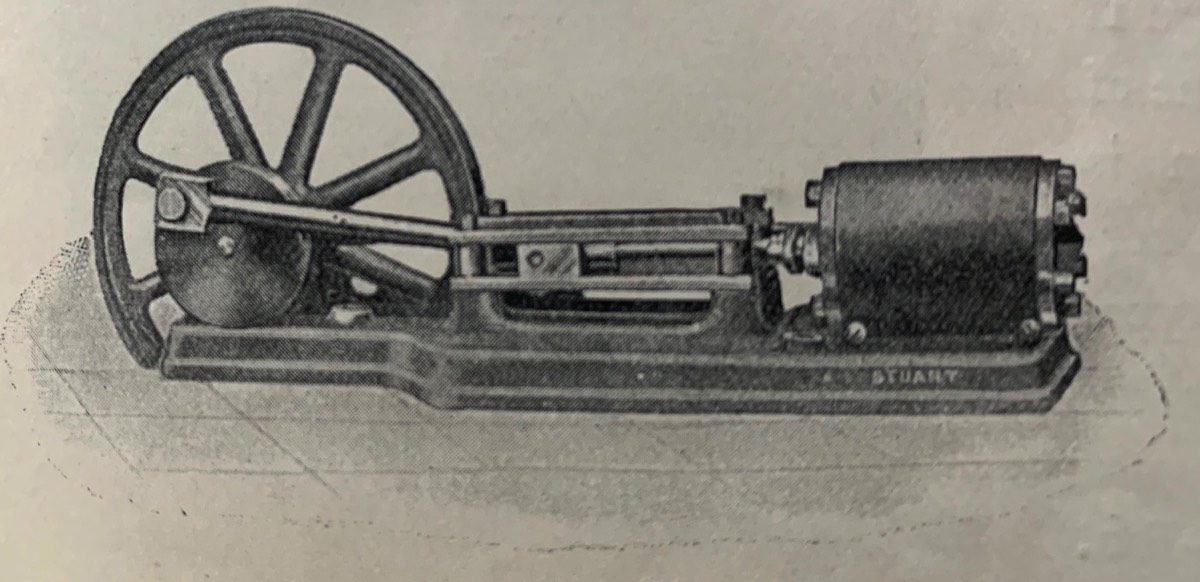

H.M. HORIZONTAL MILL.

Price., 10/6 Post Free.

Weight packed, 3-lbs.

With this range of engines Stuart has set out to provide a variety of easy to machine engines with common elements. The range of difficulty levels is ideal for the beginer machinist as clear progress can be made from the oscillators to the Mill engine. The inclusion of a simple boilers and an undertype engine really fills out the range. Collecting and machining would have been great fun.The archetypical beginners range. It suprises me that whilst some were available for several years the undertype and mill were only available for a few years. The Mill engine was similar in design to the S50 available at the same time, maybe this was why the mill was dropped. The oscillators both consist of a small steel lagged cylinder with an oval piston rod gland. in the horizontal version the soleplate mounts the Pivot for the cylinder and the valve ports machined in, the crankshaft is held in a single bearing brass drilled into the same. A small oil hole or oil cup was added.The crank is simply machined to provide counterweight. A small cast iron fly wheel is fitted. The soleplate fits on a small cast iron box bed. Interestingly this engine has been recently re-released. The vertical engine utilises an open "A" frame with the cylinder pivot at the top and the crank at the bottom, the same crank is fitted but a small disc wheel is fitted instead. In 1928 the ST was released with a slightly smaller bore and a solid frame design. The Undertype engine is a copy of a typical semi permenant engine that combines engine and boiler in a single transportable design. The engine is the same as the S.H. with the soleplate extended to allow the boiler to be fitted at both ends. The engine cylinder is mostly hidden in the forward boiler mount which surrounds it. The Base casting is raised to provide the crosshead guides with upper guides fashoned from stock steel. The crank bearings are holes drilled into raised support webs.The boiler has a steel cladding, a smokebox door, chimney, water level guage, safety valve, a false fire door and a cutout for placing a small meths burner, probably of similar design to that used on the Stuart ST plant boiler. The separate boiler doesnt have the extended baseplate for the engine and instead has a tubular support at the front. It also has a second fitting in the top to mount a steam valve for controling a connected engine. The Undertype engine has a pipe from the smokebox to the mounted engine hidden in the shroud that holds up the front of the engine. The S.V. is a traditional vertical twin standard type engine. The cylinder on top has a standard type valve chest with the cover being decorated with a raised cross design cast in. Several of stuarts small engines have featured cast in decorations. For simplicity it uses a single web crank and a small marine type disc wheel. No box bed was provided and the engine required to be fitted to some kind of mounting as the disc wheel and crank both protude below the soleplate. The picture below shows some spacers added for lifting the engine clear. The eccentric strap is split and incorporates the rod. Most simple model engines used a non split eccentric strap which makes compensating for wear difficult. The S.H. engine has a combined soleplate and box bed. Extending from one end is a cylinder mounting extension, this reduces the amount of metal required and reflects real engine designs. The casting has raised supports for the crosshead guides, consisting of two plates each side with spacers. The connecting rod has holes drilled at each end instead of separate brasses. The crank is neatly designed to provide counterweight providing for smooth running. Split eccentric strap and standard slide valve operation as on most other engines in this series. The crankshaft has two separate bearing brasses for support. This is basically the same as on the Undertype engine. The H.M. is another variation on a theme, using similar components as the S.H. but mounted on a ground level soleplate, such as was popular in full size mill engines. This requires a pit for the flywheel to run in. The cylinder, croshhead, crankshaft, valve gear is pretty much the same. The two main differences are the full round crankwheel with crank pin that the connecting rod connects to. The second is the larger 8 spoke flywheel as opposed to the 6 spoke used on several of the other engines.

Please Consider Making a Donation