- © 2018 Steve Allen Contact Me 0

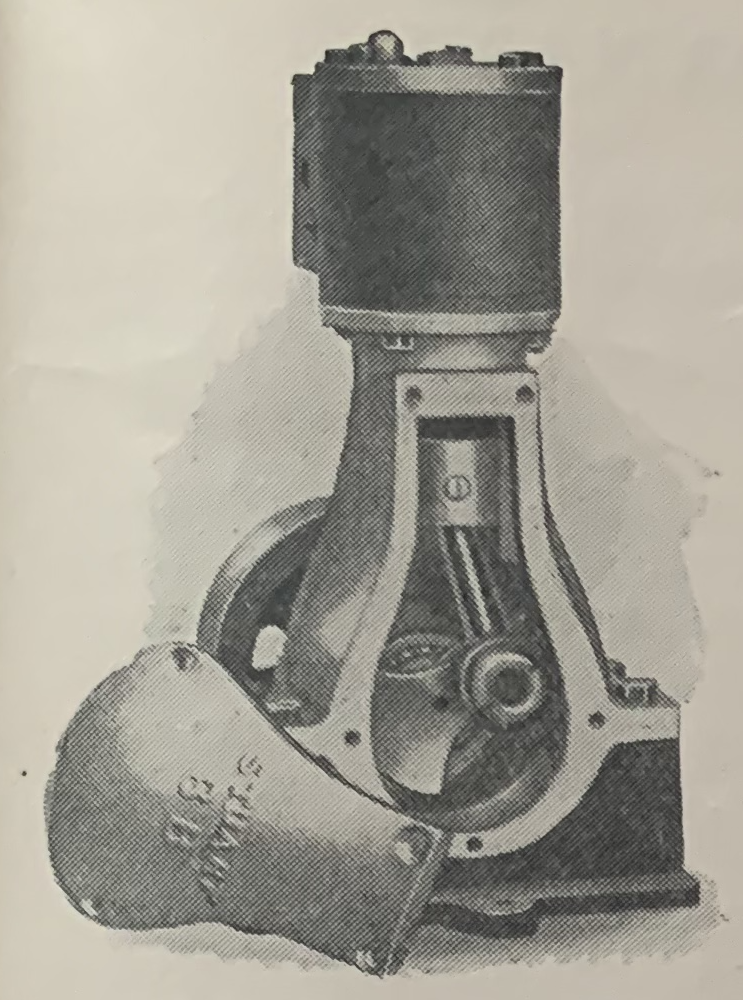

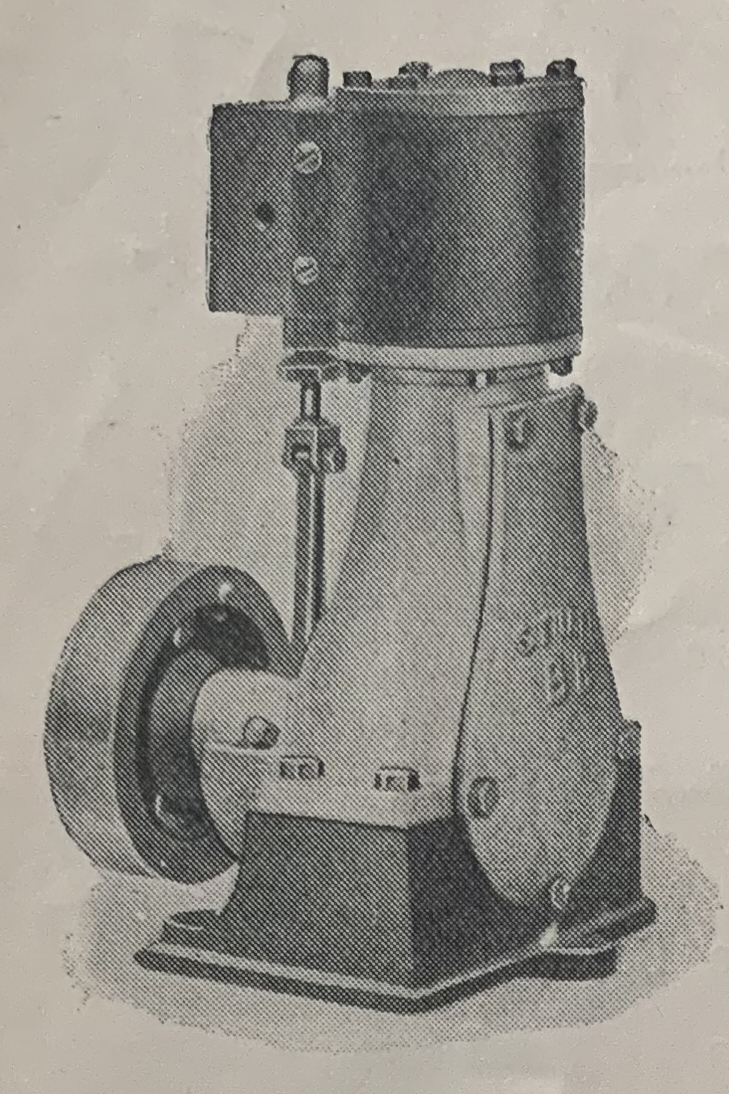

STUART B.B.

Fully machined set of castings and parts with all bolts, nuts and screws, full instructions and drawings ….. 21/- post free.

Ditto, with all holes accurately drilled and tapped …. 30/- post free.

Machined Box Bed and 4 bolts, 2/- extra.

FINISHED ENGINE, built in our workshops, and tested under steam …. £3 post free.

Fitted with drain cocks and cylinder lubricator, 6/3 extra. Mounted on box bed, 2/6 extra.

Foreign orders should include Postage for 2-lbs.

STUART B.B.

_______________________

¾-in. Bore x ⅝-in. Stroke.

Height from bottom of Crank Case, 4½-in.

Weight without Flywheel, 17-ozs.

Weight of Flywheel, 4-ozs.

____________________________

A ball bearing, enclosed, high speed engine, with aluminium crank case, for the heaviest duty and continuous running.

B.B.

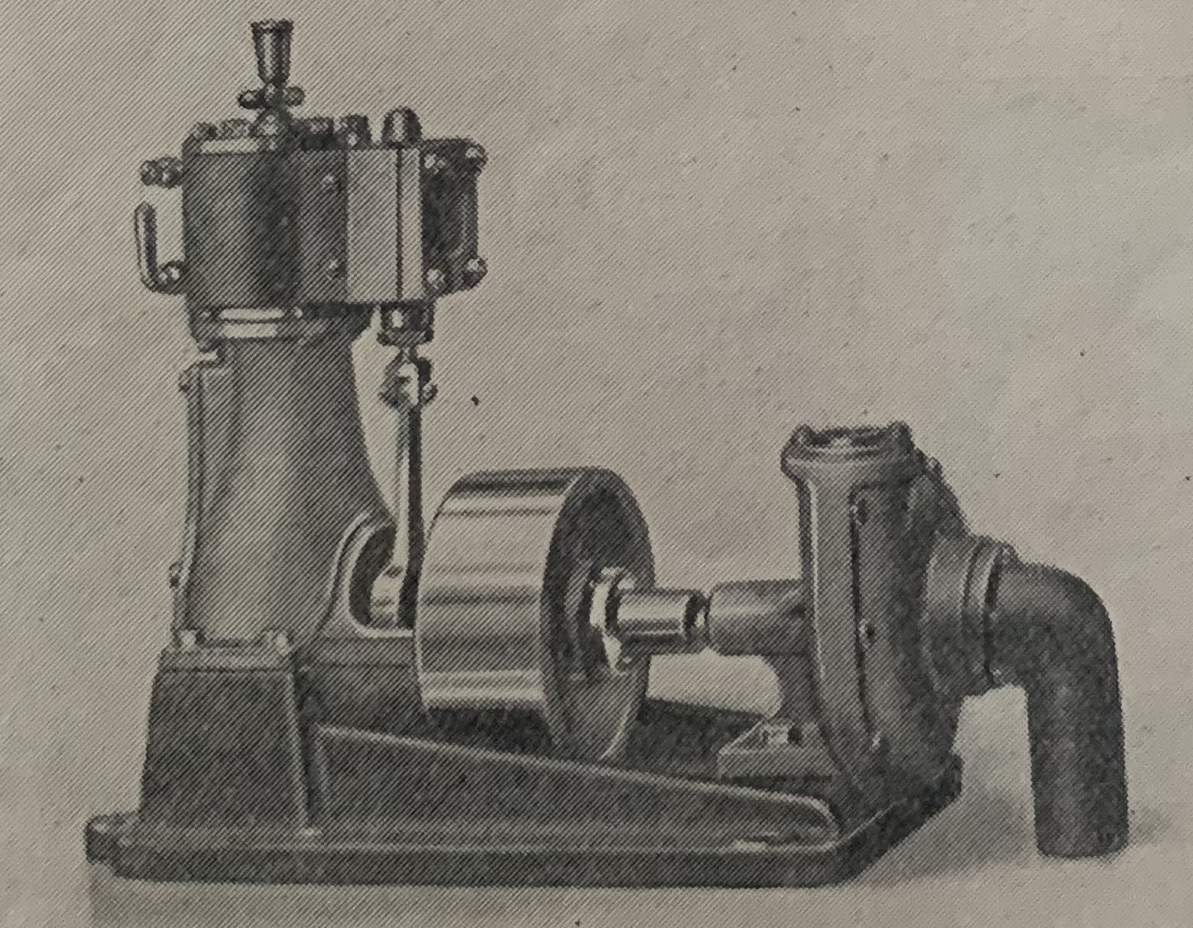

Direct Coupled Plants

____________

The B.B., being a very high speed engine, is most suitable for direct coupling to a dynamo or centrifugal pump. Special bases for this purpose are shown on page 60. The pump is on page 27. The plant can be built without a lathe. As illustrated, finished and tested in our works,

£4 10s. 0d.

This engine is a departure from the normal Stuart engines, most noticable in its futuristic looks. The use of aluminium for the main body allow for a nice highly polished finish. The Cylinder is of an oversquare design where the stroke is shorter than the bore, this imcreases the speed at the expense of power. The rating of 4,000 rpm makes it ideal for a dynamo or pump. Both of which were catered for with baseplates to fit already available units. The crankshaft ran in a Ballbearing hence the BB name, reducing wear and allowing the fast operating speed, A large hollow crankpin and counterbalances crank, also improved speed. The closed crankcase allows for wet sump lubrication. Partially filling the crankcase with oil allows for the crank to splash oil all over the crankshaft, bearing, trunk guides, and bottom of the piston lubricating most of the cylinder. This extends to the outside of the crankcase as the eccentric is mounted in an extension bath. The crankshaft leaves the bath through a bearing point lubricated by a pressurised grease fitting. (similar to the grease fitting used on the water pump shaft to prevent leakage.) The effect of all these design features is an extremely smooth running engine and free running engine. Almost no vibrations even when running at high speed.

Please Consider Making a Donation