- © 2018 Steve Allen Contact Me 0

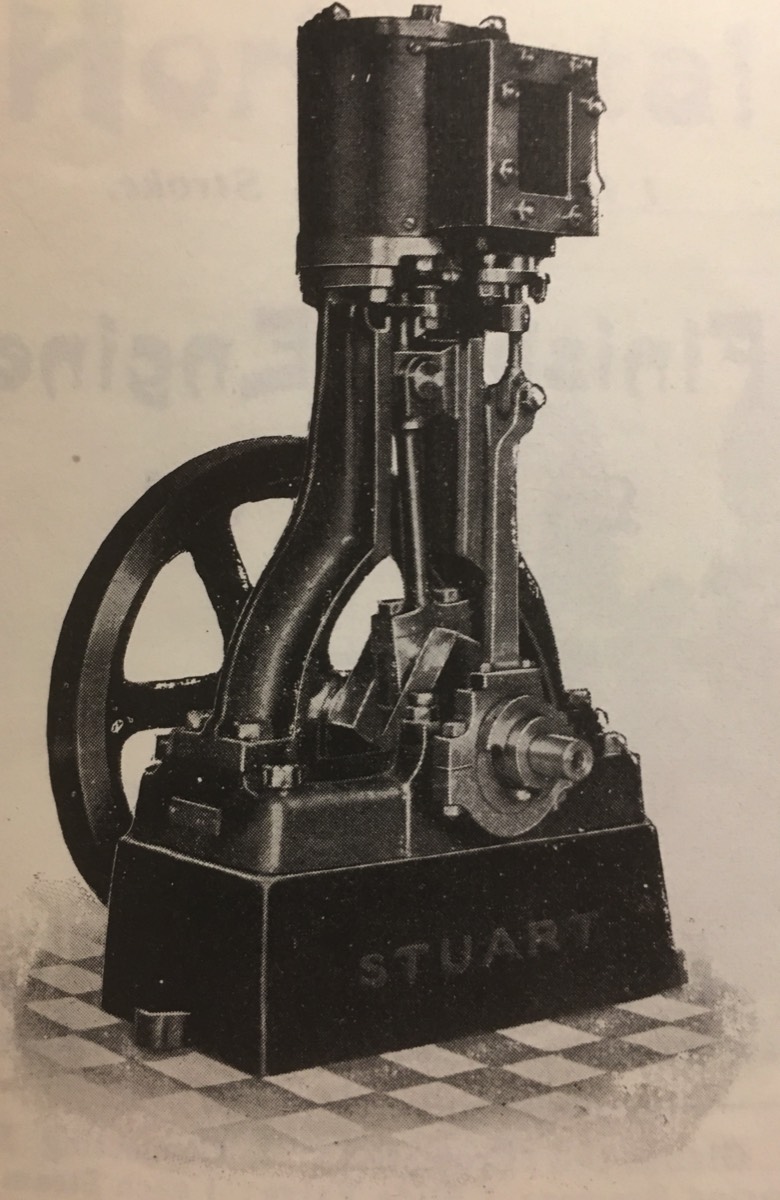

No.5

2 in. Bore, 2 in. Stroke.

Finished Engine

£7 10s. 0d.

With Slip Eccentric.

£7 15s. 0d.

Or Fitted with

Reversing Gear.

£9 0s. 0d.

List of Castings and Parts

CAST IRON.- Cylinder with steam and exhaust ports cast in; 1 Bottom, 1 Cover, 2 Piston Bodies, 1 Valve Chest, 1Valve Chest Cover, 2 Standards, 1 Bed Plate, 1 Box Bed, 1 Eccentric Sheave, 1 Flywheel, 1 Collar.

CAST STEEL.- 1 Connecting Rod, 1 Crank Shaft, 1 Front Column, 1 Eccentric Rod.

GUN METAL.- 1 Piston Gland, 1 Valve Gland, 2 Eccentric Straps, 2 Main Bearing Brasses, 2 Main Bearing Caps, 2 Connecting Rod Brasses,; 1 Valve Spindle Guide, 1 Valve Nut; 1 each Steam and Exhaust Flanges.

MILD STEEL. etc.- 2 Crosshead Guide Plates, Cylinder Lagging, Valve Rod, Steel for Valve Rod Head and Crosshead Bolt, finished steel Piston Ring, Forged Piston Rod with Crosshead.

DRAWINGS.- A large sheet showing all details full size.

Price, packed in strong box = = 22/6

⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯

EXTRAS

All Studs, Bolts, Nuts and Screws. Price 8/-

Cylinder Drain Cocks, 3/- per pair. Cylinder Lubricator, 2/- Reversing Gear, with Link Motion,-Castings in Steel and Gun-Metal, with all Bolts, Screws, etc., with Drawing, price 6/6.

Many enquiries having been received for a Double Standard Engine, we have produced this one. It will be seen from the above photo, that the engine being fitted with slip eccentric gear can run in either direction, this is included in the set. If Link Motion Reversing gear is required, price will be as above.

The No 1 has evolved again, this time into a 2 direction engine, with a choice of reversing mechanisms. This time Stuart has made it quite clear the engine has been produced at the request of customers, as can be seen from the last paragraph on the previous page. The inclusion of slip reversing gear allows the engine rotation direction to be changed whilst the engine is stopped. The importance of two standards so that the crosshead is fully supported in both directions is clear. The option of Stephenson reversing gear as an optional extra allows for those who need more flexible control of speed and also notching down to conserve steam. Constructionally the engine has 4 main differences and an extra Standard compared to the No.1 kit of parts. The replacement of the rod with a second Standard requires a change to the soleplate design. Instead of a small angled mounting for the rod the soleplate is now symmetrical with flat surfaces for both Standards. The Cylinder Bottom cap now has to be changed to remove the lobe for the Rod mounting and have symmetrical mountings for the two Standards. The Crosshead is also a symmetrical design with two bearing surfaces to run in the two standards. A steel forging combined this with the piston rod. The replacement of standard eccentric, rod and straps with a newly designed slip eccentric rounds off the changes. The new eccentric rod now has a flat on the end that bolts to the strap with two bolts instead of the old side mounted single bolt design.

The new Crosshead now has two bearing surfaces that have to be machined accurately and symmetrical. Machining two Standards requires a bit more than double the effort as they have to be dimensionally the same. On the No.1 the rod could be machined to match the gap after assembly of the Cylinder Bottom, Standard and Soleplate. Finishing and assembling would be more complicated than the No.1 requiring that after assembling the cylinder unit, one of the standards be attached carefully aligning with the Crosshead to avoid tight spots. The second Standard should then be attached to also avoid tight spots. Now the unit can be positioned on the Soleplate and aligned to the Crankshaft and Connecting rod. At this point i would drill the holes for mounting the Standards to the Soleplate. As a restorer of Stuart steam engines I often find that the mounting holes, whilst appearing in the correct position, have been enlarged to allow smooth running. I have thus developed a more hand fitted approach to engines. Steam engines are designed such that accuracy is required. Any mistakes in marking out will often combine and add up to prevent correct functioning. So many engines I come across have shims, washers, oval holes, plugged holes, etc... and require no end of reworking to get running smoothly. I have developed a philosophy of identifying which measurements should be taken from the drawing and which should be machined to fit.

Split Eccentric Reverse Gear.

Please Consider Making a Donation