- © 2018 Steve Allen Contact Me 0

HiGH SPEED ENCLOSED

SINGLE ACTING ENGINES

With Balanced Pistons.

Up-to-date designs, specially suitable for

FAST MODEL TORPEDO BOAT DESTROYERS

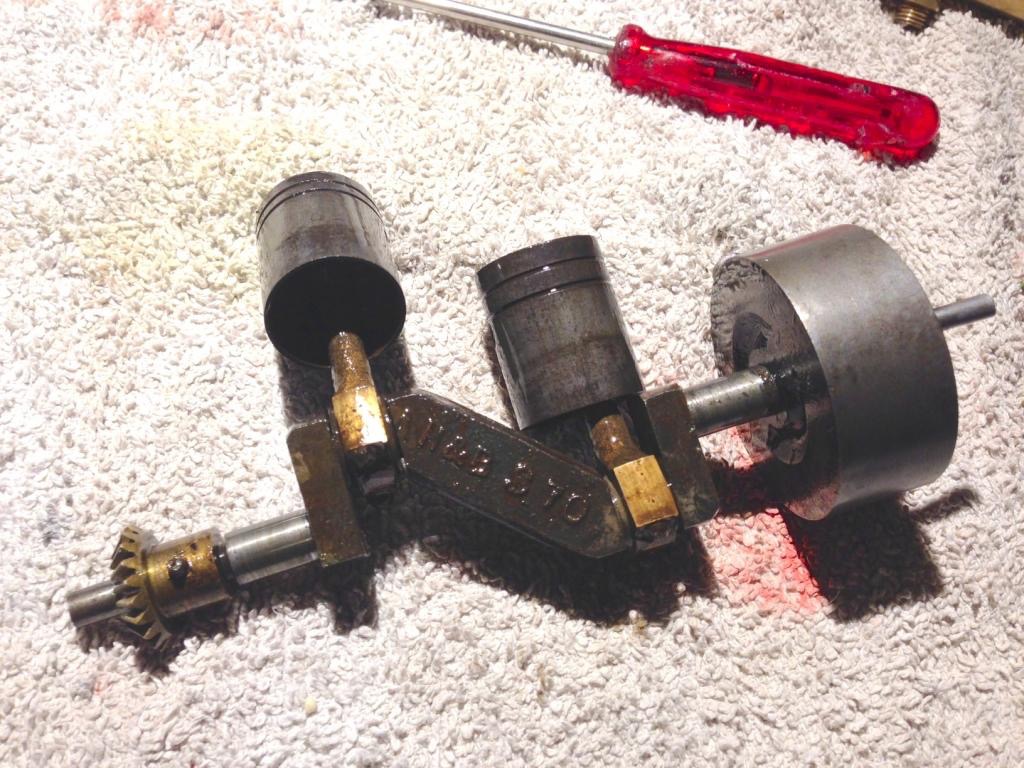

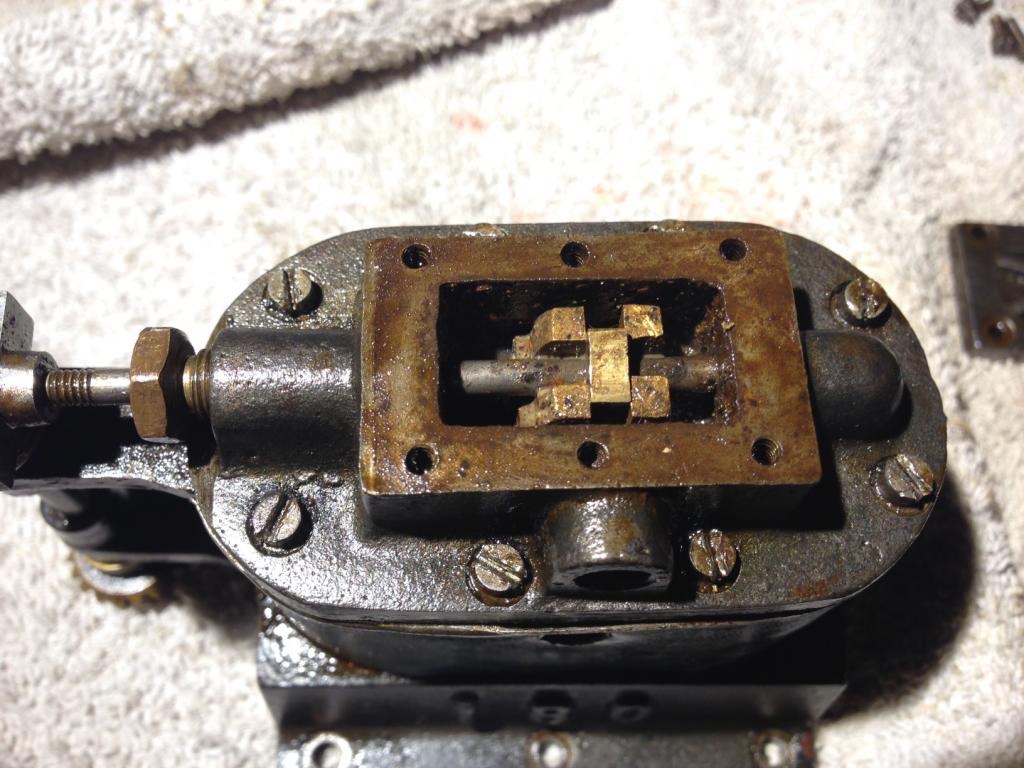

With increasing interest in model high speed steam boats and competition from other manufacturers, Stuart decided to add to the Stuart BB, a range of twin cylinder engines. Reqirements for a high speed boat differ greatly from normal steam boats. They require Light weight, Low height, small bed space, high speed running, low vibration, simple design. To achieve all these requirements an number of features conveniently combine to create avery nice model boat engine. The engines are all variations on the same theme but with slightly different capabilities. I will deal with individual characteristics on the seperate engine pages but here I will concentrate on the overall design features. To reduce the height and weight of the engines Stuart removed the piston rod and gland and mounted the small end of the connecting rod directly to a gudgeon pin mounted in the top of hollowed pistons, not unlike the pistons in an Internal Combustion Engine. The pistones being hollow alows a long piston with a small sealing surface with eirther sealing grooves or piston rings. This reduces the height considerably. Having the pistons directly above the crankshaft and mounting it in a wet sump oil bath allows oil splashed up from the crankshaft to lubricate the bottom of the cylinders which is dragged up the bore by the pistons. It also lubricates the gudgeon pin. Valving a single cylinder in double acting mode ( piston pushed up and down by steam in two strokes.) would be very complex so by mounting two cylinders side by side in single acting mode (piston only pushed down by steam) allows for very simple valving. The slide valve is mounted in a top casting allows for very simple machining. Control of the valve varied with the different engines being a cam, eccentric or bevel gears. The twin cylinder arrangement also reduced vibrations considerable as whilst one goes up the other goes down, balancing each other out. Construction is essentially the same with a top casting containing the valve, a middle casting with the twin cylinders cast in with a light weight structure and a bottom casting consisting of an oil sump and mounting brackets. The crankshaft bearings are cast into the bottom and middle castings on the joint line. The oil level was filled up to a point bellow this split line to reduce leakage, the crankshaft splashing into the oil easily moved it arround the inside of the engine. The bearing surfaces must have proved troublesome as in all later engines seperate bearings were mounted onto the castings. Steel clading was mounted over the cylinders to reduce condensation and maintain heat once the engine has started up. The exposed valve gearing was a bit of a problem being difficult to maintain lubrication and easily damaged. Later designs enclosed the gears.

Please Consider Making a Donation